Ever wondered what is a unistrut and why it’s so popular in construction and industrial projects? Unistrut is a generic term for a modular framing system featuring a U-shaped channel profile. These strut channels are designed to support and organize everything from electrical conduit and cable trays to solar panels and HVAC equipment. The magic lies in their modularity—channels, nuts, and fittings combine to create endless support structures that can be assembled, reconfigured, or expanded without welding or specialized tools.

When you choose aluminum unistrut over traditional steel, you’re opting for a lighter, corrosion-resistant, and easier-to-handle system. Imagine installing rooftop solar supports or cable trays overhead—aluminum strut channel makes the job faster, safer, and less physically demanding.

Let’s break down the main differences between aluminum strut and steel channel framing. Aluminum’s key strengths are its low weight and natural resistance to corrosion, making it perfect for outdoor, marine, or cleanroom environments. Steel, by contrast, is the go-to for heavy-duty, long-span, or high-impact applications where maximum load capacity is critical.

As a rule of thumb: Aluminum struts can cut system weight by half, but expect about a third less maximum load capacity compared to equivalent steel channels. Always match the material to your project’s real demands.

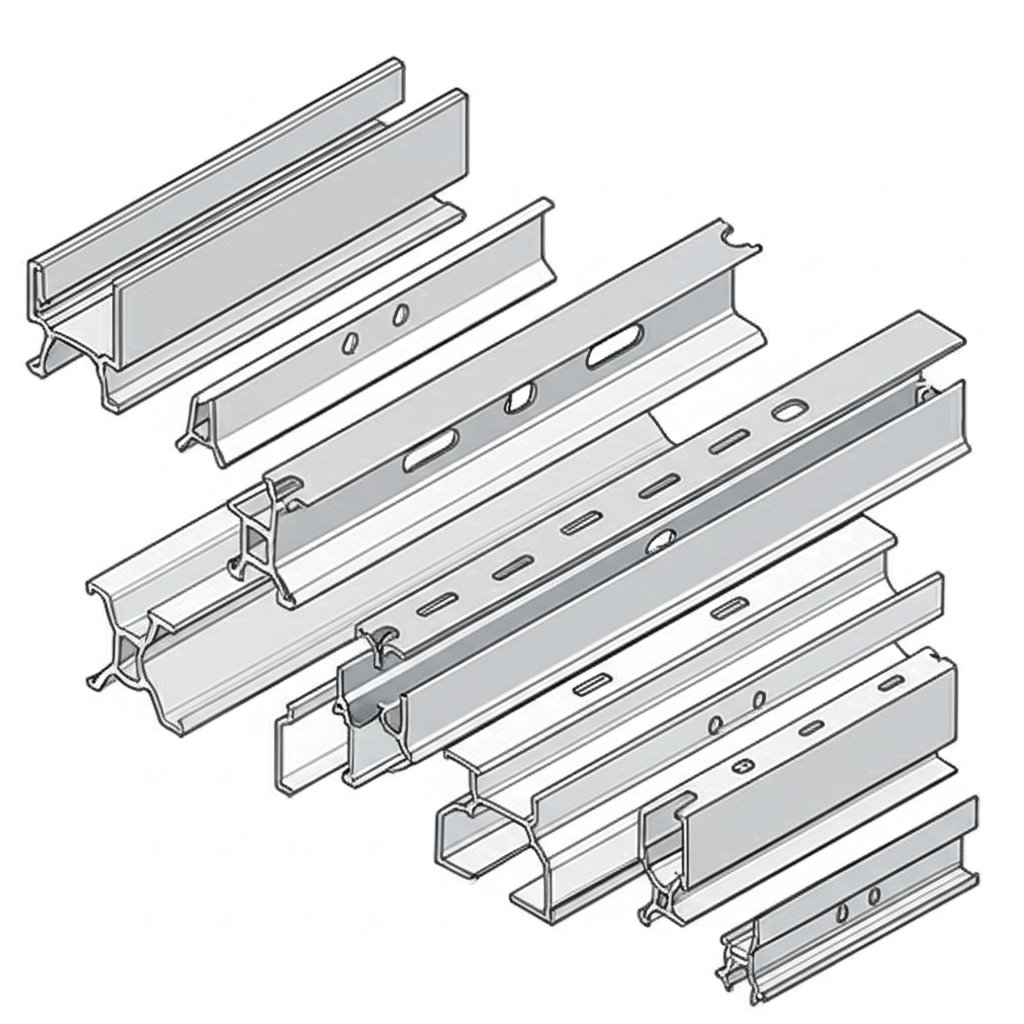

Aluminum unistrut comes in a variety of sizes to suit different needs. The most common is the 1-5/8 inch profile, which balances strength and versatility for electrical, solar, and light mechanical framing. Mini and shallow profiles are also available for compact or architectural applications. Channels may feature continuous slots (for maximum adjustability) or solid webs (for higher load ratings).

| Use Case | Recommended Channel Depth | Slot Type |

|---|---|---|

| Electrical / Data Tray Support | Shallow or 1-5/8" | Slotted |

| Solar Panel Framing | 1-5/8" (deep) | Solid or Slotted |

| Architectural Shelving | Mini / Shallow | Slotted |

| Light Industrial Machine Guard | 1-5/8" | Solid |

What sets unistrut aluminum apart is its modular system of spring nuts, channel nuts, brackets, and specialty fittings. These accessories allow you to assemble, expand, or reconfigure frameworks without welding or drilling. Spring nuts snap into the channel and provide a strong, adjustable anchor point for brackets, clamps, or equipment. With a wide range of fittings—angles, plates, clamps, and more—aluminum struts can be adapted for everything from rooftop pipe supports to custom shelving and machine frames.

For projects that need custom extrusions, OEM supply, or engineered accessories aligned to aluminum unistrut requirements, consider aluminum extrusion profiles China from Shengxin, a professional aluminum profile manufacturer. They offer tailored channels, brackets, and finish options to match your specific application needs.

In summary, aluminum unistrut brings unmatched modularity, reusability, and adaptability to modern construction, building services, solar, and light industrial framing. Whether you’re supporting cable trays, building architectural features, or designing corrosion-resistant frameworks, aluminum struts deliver a clean, efficient, and future-ready solution.

When you’re specifying an extruded aluminum strut for your project, understanding the material’s mechanical properties is essential. Most aluminum unistrut channels are manufactured from 6063-T6 alloy, prized for its balance of strength, corrosion resistance, and workability. Closure strips may use 6063-T5, while fittings and accessories often use 5052-H32 alloy. But what do these designations mean in practice?

| Alloy | Temper | E (ksi) | Fy (ksi) | Fu (ksi) | Density (lb/in³) | Finish Options | ASTM Reference |

|---|---|---|---|---|---|---|---|

| 6063 | T6 | 10,000 | 21 | 27 | 0.097 | Mill, Anodized | ASTM B221 |

| 6063 | T5 | 10,000 | 16 | 22 | 0.097 | Mill, Anodized | ASTM B221 |

| 5052 | H32 | 10,200 | 28 | 33 | 0.097 | Mill | ASTM B209 |

For most aluminum channel strut applications, 6063-T6 is the standard, offering a reliable combination of strength and corrosion resistance. Always check the manufacturer’s datasheet for the exact unistrut channel specifications before finalizing your design.

Sounds complex? It doesn’t have to be. When you look at strut channel sizes, you’ll notice each profile comes with a set of section properties—these numbers are the backbone of structural calculations. Here’s a quick guide to the most important properties:

Let’s see how these play out for some typical aluminum slotted channel profiles:

| Profile | Area (in²) | Ix (in⁴) | Iy (in⁴) | Sx (in³) | Sy (in³) | Weight (lb/ft) | Slot Factor | Notes |

|---|---|---|---|---|---|---|---|---|

| B22AL (1-5/8" x 1-5/8", 0.105" thick) | 0.23 | 0.296 | 0.120 | 0.363 | 0.147 | 0.66 | 0.95 | Slotting reduces section by ~5% |

| B12AL (2-7/16" x 1-5/8", 0.105" thick) | 0.31 | 0.473 | 0.164 | 0.527 | 0.202 | 0.86 | 0.95 | Slotting reduces section by ~5% |

| B54AL (13/16" x 1-5/8", 0.080" thick) | 0.11 | 0.081 | 0.032 | 0.137 | 0.051 | 0.37 | 0.95 | Use for light-duty support only |

Note: Section properties are representative. Always confirm dimensions and tolerances for your selected profile in the manufacturer’s catalog. Slot patterns, hole size, and web thickness can affect both strength and stiffness.

Published section properties assume a straight, undamaged channel. If your aluminum unistrut channel is cut, drilled, or slotted beyond standard patterns, reduce allowable loads accordingly.

Choosing between slotted and solid aluminum unistrut channels depends on your project’s needs. Slotted channels offer maximum flexibility for bracket placement and adjustment, perfect for electrical and data tray supports. Solid channels provide higher load capacity and are best for long spans or heavy-duty framing where adjustability is less critical.

Most aluminum channel strut is supplied with a mill finish, which is suitable for most indoor and mild outdoor environments. For harsher settings or architectural applications, anodized finishes add an extra layer of corrosion resistance and an attractive appearance. Always match the finish to your environment and project specs.

In summary, understanding material standards, section properties, and finish options is the foundation of reliable aluminum strut channel design. For the most accurate results, download manufacturer CAD files and datasheets to verify unistrut channel specifications and strut channel sizes before you build. Next, we’ll see how these properties translate into real-world span and load capacities.

Ever wondered how much weight a 1 5/8 strut channel can safely support? Or how to use those dense-looking load tables for your next project? Let’s break it down. The unistrut channel p1000 is the industry standard for aluminum framing—its load capacity is the benchmark for most light-to-medium duty support jobs. But not all p1000 struts are created equal. Load ratings depend on span, support conditions, slotting, and the type of load (uniform or point).

Load tables for p1000 unistrut channels provide the total allowable uniform load (in pounds) for a given span. If you need the load per foot, simply divide the table value by the span length. These tables also include columns for deflection limits—like L/180, L/240, or L/360—so you can design for both strength and serviceability. Here’s a simplified example for a 1-5/8" solid aluminum channel (6063-T6):

| Span (ft) |

Allowable Uniform Load (lbs) (L/180) |

Allowable Uniform Load (lbs) (L/240) |

Allowable Uniform Load (lbs) (L/360) |

Notes |

|---|---|---|---|---|

| 2 | 1630 | 1370 | 1020 | Solid web |

| 3 | 1070 | 900 | 670 | Solid web |

| 4 | 820 | 690 | 510 | Solid web |

| 5 | 680 | 570 | 420 | Solid web |

| 6 | 570 | 470 | 350 | Solid web |

| 8 | 420 | 340 | 250 | Solid web |

| For slotted channels, apply a reduction factor (typically 0.85–0.95) depending on slot pattern. | ||||

Need to support a heavy piece of equipment at the center? Point loads are a different story. The allowable point load at midspan is usually about 50% of the uniform load for the same span and deflection limit.

| Span (ft) | Allowable Point Load at Midspan (lbs) |

Allowable Cantilever Tip Load (lbs) (2 ft overhang) |

Notes |

|---|---|---|---|

| 3 | 450 | 200 | Solid web |

| 4 | 340 | 150 | Solid web |

| 5 | 290 | 110 | Solid web |

| 6 | 240 | 90 | Solid web |

Why do deflection limits matter? Imagine a cable tray that sags too much—wires could pull loose, or water might pool and cause corrosion. That’s why most specs require a maximum deflection (the amount a beam bends under load), often expressed as a fraction of the span (L/180, L/240, etc). For example, with a 6-foot span and an L/180 limit, the maximum allowed deflection is 0.4 inches (6 ft × 12 in/ft ÷ 180).

When reading p1000 strut load tables, always check which deflection column applies to your project. Loads in the L/180 column will be higher than those for L/240 or L/360, but you may risk excessive sag if you ignore the stricter limits. Serviceability often governs the design of unistrut p1000 systems in real-world installations.

Want to boost your p1000 unistrut load capacity? Using two channels back-to-back (sometimes called a double channel) can nearly double the allowable load and cut deflection. This approach is common for long spans or heavy point loads. Just be sure to connect the channels properly with recommended hardware, and verify the assembly meets your project’s requirements.

Cantilevered conditions (like a sign arm or overhanging bracket) dramatically reduce capacity. Always use load tables specific to cantilevered supports, or consult a structural engineer for custom scenarios.

Aluminum is an excellent choice for most light and medium-duty supports, but if your calculated loads or spans exceed the published values, it’s time to consider steel. Steel channels offer roughly three times the load capacity for the same profile—ideal for seismic bracing, high-impact areas, or long unsupported runs.

Always verify local code requirements and consider connection stiffness, as bolt slip or flexible fittings can lower the effective capacity of your unistrut channel p1000 system. When in doubt, consult manufacturer engineering resources or a licensed structural engineer for final checks. Next, we’ll walk through real-world calculation examples so you can apply these principles directly to your project.

Ever wondered how to size a 1 5 8 strut channel for a cable tray? Let’s break down the process using real numbers and clear steps, so you can confidently handle your next project or review a unistrut cad drawing.

| Example | Span (ft) | Load (lb/ft) | Ix (in4) | Sx (in3) | σallow (ksi) | Δallow (in) | Result |

|---|---|---|---|---|---|---|---|

| Cable Tray | 6 | 30 | 0.296 | 0.363 | 21 | 0.4 | Strength OK, Deflection NG |

Imagine mounting a shelf for equipment using a solid strut channel. Here’s how the numbers work out:

| Example | Span (ft) | Load (lbs) | Ix (in4) | Sx (in3) | σallow (ksi) | Δallow (in) | Result |

|---|---|---|---|---|---|---|---|

| Shelf | 4 | 120 | 0.296 | 0.363 | 21 | 0.27 | Strength OK, Deflection NG |

Need to support a signage arm? Cantilevered loads are much more demanding on aluminum struts:

| Example | Span (ft) | Tip Load (lbs) | Ix (in4) | Sx (in3) | σallow (ksi) | Δallow (in) | Result |

|---|---|---|---|---|---|---|---|

| Sign Arm | 2 (cant.) | 80 | 0.296 | 0.363 | 21 | 0.13 | Strength OK, Deflection NG |

For heavier HVAC pipes, a double strut (back-to-back assembly) can dramatically increase capacity. Assume section properties double: Ix = 0.592 in4, Sx = 0.726 in3.

| Example | Span (ft) | Load (lb/ft) | Ix (in4) | Sx (in3) | σallow (ksi) | Δallow (in) | Result |

|---|---|---|---|---|---|---|---|

| HVAC Pipe | 6 | 60 | 0.592 | 0.726 | 21 | 0.4 | Strength OK, Deflection NG (but improved) |

If you’re swapping a steel 1 5 8 strut for aluminum with the same geometry, expect about 1/3 the load capacity due to lower modulus and yield strength. Always re-calculate both strength and deflection, and check the latest unistrut cad or manufacturer tables for your exact 1 5 8 unistrut load capacity.

Don’t forget: The channel is just one part of the system. Always verify the capacity of fittings, anchors, and connections—these often control the true safe load, especially with solid strut channel or double assemblies.

By following these step-by-step calculations, you’ll know exactly how to select the right aluminum strut for your project, whether you’re designing a cable tray, shelf, signage arm, or heavy-duty pipe support. For more complex geometries or to verify your work, consult manufacturer datasheets, unistrut cad files, and a licensed engineer as needed. Up next: see how these numbers play out in real-world installations and case studies.

When you’re weighing options for strut construction, the choice between aluminum and steel isn’t just about strength—it's about total project value. Imagine mounting cable trays in a data center, supporting solar panels on a rooftop, or building lightweight machine guards in a factory. In these scenarios, aluminum unistrut often outshines its steel counterpart by offering a blend of lightness, corrosion resistance, and installation speed.

| Metric | Aluminum Strut | Steel Strut |

|---|---|---|

| Weight per Foot | ~0.66 lb (1-5/8" x 1-5/8") | ~1.8 lb (1-5/8" x 1-5/8") |

| Installed Labor | Lower (easy handling, faster cuts) | Higher (heavier, harder to cut) |

| Corrosion Resistance | Excellent (natural oxide layer) | Good (galvanized), Moderate (plain) |

| Repaint Cycles | None (typical) | Periodic (especially in outdoor/coastal) |

| Recyclability | High (fully recyclable) | High (but energy-intensive) |

| Total Cost of Ownership | Often lower (labor + maintenance savings) | Higher (material + labor + repainting) |

Let’s put these numbers to work with real-world examples. Aluminum electrical strut channels are a top pick for supporting conduit and cable trays, especially in high-humidity or corrosive settings. Their non-conductive properties (when anodized or coated) also reduce the risk of electrical faults—a critical safety advantage in metal framing strut systems for electrical rooms or data centers.

Sounds like aluminum is always the answer? Not quite. While the up-front price per foot is higher, the total installed cost often tells a different story. Consider a 1-5/8" channel for a rooftop solar project:

For light and medium-duty jobs, aluminum’s lower weight slashes labor costs and makes handling safer, especially on rooftops or overhead. When you factor in zero repaint cycles and minimal corrosion risk, the lifecycle cost of aluminum strut construction can be lower than steel, particularly for electrical, solar, or architectural work in harsh environments.

Ever lifted a 20-foot steel channel onto a ladder? With lightweight unistrut, installers handle less than half the weight—reducing fatigue, lowering injury risk, and speeding up the job. In settings where every pound matters (think: high-rise rooftops, cleanrooms, or seismic zones), aluminum’s ergonomic edge is hard to beat.

Key insight: If your project is exposed to weather, requires frequent reconfiguration, or demands fast, safe handling—aluminum strut is often worth the higher per-foot material cost, thanks to savings in labor, maintenance, and long-term durability.

As you plan your next metal strut installation, consider not just the sticker price, but the total impact on speed, safety, and lifecycle value. Up next, we’ll explore how to ensure compatibility and long-term corrosion resistance for your aluminum framing system.

When you’re piecing together an aluminum unistrut framework, it’s easy to focus on channel size and span—yet, the real headaches often come from hardware compatibility and corrosion surprises. Ever noticed white powder or pitting where your aluminum channel meets a bracket or bolt? That’s galvanic corrosion in action, and it can quietly undermine your installation’s life span.

Let’s make it simple: the combination of aluminum channels with different strut channel fittings and fasteners requires careful material selection. Here’s a practical compatibility overview to help you avoid costly mistakes:

| Accessory/Hardware Material | Risk with Aluminum Channel | Recommended Isolator or Mitigation |

|---|---|---|

| Stainless Steel Unistrut / Fasteners | Moderate (galvanic risk in wet or marine zones) | Use nylon or polymer washers; consider dielectric paste |

| Galvanized Strut / Zinc-Plated Hardware | High (zinc and aluminum are far apart on galvanic scale) | Always use isolating pads or sleeves; avoid direct contact |

| Polymer-Coated or All-Polymer Fittings | Low (no galvanic reaction) | Best for harsh or marine environments |

| Plain Carbon Steel | High (rapid corrosion, not recommended) | Avoid; if unavoidable, use full isolation and sealant |

Mixing aluminum channels with stainless steel unistrut or galvanized strut components is common, but never ignore the need for isolators. Even a little condensation or rain can turn a minor material mismatch into a major corrosion problem.

Sounds complex? It’s really about electricity and chemistry. When two dissimilar metals touch in the presence of moisture, one becomes the “anode” (corrodes faster), and the other the “cathode.” Aluminum is typically more anodic than stainless steel or zinc, so it will corrode first. This is why direct contact between aluminum and galvanized unistrut or stainless steel strut hardware in damp locations can accelerate channel deterioration.

Key tip: The more aggressive the environment (outdoor, marine, or industrial), the more critical it is to break the electrical path between aluminum and other metals.

When your project faces tough conditions—think coastal rooftops, food processing plants, or chemical facilities—hardware selection becomes mission-critical. Here’s a quick pros and cons rundown for the most common strut hardware choices:

For most outdoor or corrosive environments, pairing aluminum channels with stainless unistrut channel accessories and proper isolators is a safe bet. In truly aggressive settings, all-polymer hardware or specialized barrier coatings may be warranted.

You’ve chosen the right hardware—now, field practices make all the difference. Here’s a checklist you can use on every aluminum unistrut installation:

Regular inspection and maintenance—tightening loose fittings, checking for early corrosion, and cleaning—are essential for long-term reliability.

By combining smart hardware selection, corrosion mitigation strategies, and diligent field practices, your aluminum unistrut systems will deliver long-lasting performance—even in the harshest environments. Next, we’ll cover practical installation tips and troubleshooting to keep your framing systems in top shape year after year.

Ever installed a unistrut channel system only to find it sagging, misaligned, or corroding a few months later? You’re not alone. Even seasoned installers can overlook critical details that lead to costly rework or safety issues. Let’s break down the most common mistakes and how you can prevent them—saving time, money, and headaches on your next job.

| Symptom | Probable Cause | Verification | Fix | Preventive Action |

|---|---|---|---|---|

| Channel sags or deforms | Over-spanning, wrong profile (e.g., shallow or slotted strut instead of deep or solid unistrut) | Measure span, check profile and load vs. spec | Add supports, use deeper or double channel | Always check manufacturer load tables before install |

| Loose connections or vibration | Improper torque, wrong nut type, or missing spring nuts | Inspect channel hardware for movement under load | Re-torque fasteners, use correct channel nuts | Document torque values and re-check after loading |

| Corrosion at joints | Mixing dissimilar metals without isolation (e.g., aluminum with galvanized or plain steel) | Visual check for white powder/pitting at unistrut channel connectors | Replace hardware, add isolators or sealant | Use only compatible accessories and isolators |

| Pull-out or wall anchor failure | Improper anchor selection, missing back plates | Check anchor type, wall material, and back plate presence | Upgrade anchors, retrofit with back plates | Follow anchor manufacturer recommendations and always use back plates for heavy loads |

| Misalignment or uneven runs | Poor measurement, skipping levels or layout tools | Measure deviation from design, inspect with level | Realign or refit affected sections | Use laser or spirit level for all runs, double-check before final tightening |

Keeping your aluminum strut channel system reliable means regular inspections—especially in demanding environments or where vibration is present. Here’s a simple routine you can follow:

Quarterly inspections are recommended for high-vibration or outdoor installations; annual checks suffice for most indoor, low-risk assemblies.

Imagine you spot a sagging cable tray or hear a rattle in your strut framework. What next? Use this quick troubleshooting matrix to zero in on the root cause and solution:

| Symptom | Probable Cause | Verification | Fix | Preventive Action |

|---|---|---|---|---|

| Sagging or bowing | Over-spanned channel, insufficient profile depth | Check span vs. spec, inspect for deformation | Add intermediate supports, upgrade to deeper channel | Always match span to load table recommendations |

| Vibration/looseness | Under-torqued fittings, missing spring nuts | Test for movement under load | Re-torque, replace with proper hardware | Use correct torque and document in maintenance log |

| Corrosion at hardware | Galvanic reaction from dissimilar metals | Look for white/gray deposits or pitting | Replace with compatible hardware, add isolators | Specify only compatible materials for all connections |

Not sure whether to fix or replace a failing assembly? Here’s a quick guide:

Field tip: Document torque checks and schedule re-tightening for all unistrut channel connectors, especially on vibrating equipment or outdoor frames. A simple logbook can prevent major issues down the road.

By following these practical guidelines for installation, inspection, and troubleshooting, you’ll ensure your aluminum unistrut system remains safe, reliable, and long-lasting. Up next, we’ll look at procurement and specification best practices to help you source the right materials for your project.

Ready to specify aluminum unistrut for your next project? Clear, concise language in your drawings and RFQs saves time and ensures you get exactly what you need. Here’s a sample you can adapt:

Include these requirements in your project documents to streamline communication with strut manufacturers and suppliers—whether you’re searching for unistrut for sale locally or planning a custom extrusion run.

Imagine you’re ordering a large batch or just a few lengths for quick turnaround. Either way, a systematic approach keeps your project on track and helps you compare unistrut pricing apples-to-apples. Here’s a practical checklist:

This list ensures no detail is missed—especially when comparing unistrut suppliers near me with overseas or custom sources.

Choosing the right supplier can make or break your schedule. Here’s a comparison table to help you evaluate options for aluminum unistrut procurement. Note how custom extrusion specialists differ from local distributors and general strut manufacturers:

| Supplier | Profile Range | Custom Die Support | Finishes | Certifications | Lead Time | MOQ | Typical Unistrut Price | Cost per Foot | Warranty |

|---|---|---|---|---|---|---|---|---|---|

| Shengxin (China) | Standard & Custom | Yes | Mill, Anodized, Powder, Woodgrain | ISO, SGS, ASTM | 3-6 weeks (custom) | 500 ft (typ.) | Contact for quote | Competitive (bulk discounts) | 1 year+ |

| Local Distributor | Standard | No | Mill, Anodized (limited) | ASTM | Stock/1-2 days | 10-20 ft | $4.50–$7.00/ft | Retail | 6 months–1 year |

| General Strut Manufacturers | Standard, Some Custom | Limited | Mill, Anodized | ISO, ASTM | 2-4 weeks | 100 ft | $3.80–$6.50/ft | Varies | 1 year |

For custom profiles, OEM brackets, or engineered finishes, aluminum extrusion profiles China from Shengxin offers deep expertise and volume pricing. Local distributors are best for urgent, small runs, while major strut manufacturers provide a balance of speed and standardization.

Tempted by the lowest unistrut price per foot? Consider the bigger picture. Custom extrusions may have higher upfront costs (due to die/tooling fees and MOQs), but offer precision fit, finish control, and long-term price stability—especially for repeat or large-volume needs. Local stock may look cheaper, but rework, mismatched finishes, or limited profiles can drive up the true unistrut cost over the project lifecycle.

Remember: The lowest price per foot can be offset by rework, longer lead times, or incomplete specification coverage. Always compare total delivered value—not just sticker price.

When evaluating unistrut prices, weigh all factors: lead time, MOQ, finish, certification, and after-sales support. For urgent jobs, local suppliers or "unistrut near me" searches win on speed. For engineered projects, custom or OEM-focused manufacturers like Shengxin deliver the best fit and long-term savings.

Next, we’ll wrap up with actionable takeaways and a quick-reference checklist to help you specify and source aluminum unistrut with confidence.

Wrapping up your aluminum unistrut journey? Let’s make sure you walk away ready to specify, buy, and install with confidence. You’ve seen how this modular framing system excels in light-to-medium duty, corrosion-prone, or weight-sensitive applications. But when exactly should you choose aluminum unistrut over other options? Here’s a quick rundown:

Need a printable or shareable reference? Here’s a checklist to guide you from design to inspection:

| Application | Recommended Channel Profile | Finish |

|---|---|---|

| Electrical Tray Support | 1-5/8" x 1-5/8" slotted | Anodized |

| Solar Panel Framing | 1-5/8" deep solid | Mill or Powder Coated |

| Architectural Shelving | Mini/slotted | Anodized or Painted |

| Machine Guarding | 1-5/8" solid | Mill or Anodized |

| Custom Industrial Framing | Custom extrusion | Per project spec |

Not every project is a DIY fit. If you’re pushing span or load limits, combining materials, or working in seismic or marine environments, it’s smart to escalate to a structural engineer. Always review unistrut specs and confirm with stamped calculations for critical or code-regulated installations. For large-scale, custom, or OEM work, engineered drawings and samples ensure your solution fits first time.

Guiding principle: The right aluminum unistrut system is a balance of profile, finish, and accessories—matched to the real-world demands of your application, not just price per foot.

As you move forward, always verify local building codes, and remember to check anchors and supports—not just channel capacity. With the right planning, your aluminum inistrut installation will deliver long-lasting, adaptable, and corrosion-resistant performance for years to come.

Aluminum unistrut offers significant benefits such as lower weight for easier handling, natural corrosion resistance for outdoor or marine environments, and ease of cutting or modification on site. These features make it ideal for rooftop solar, electrical tray supports, and architectural applications where speed, safety, and durability matter most.

Selecting the right profile involves matching channel depth and slotting to your load and span requirements. For light to medium-duty supports, the 1-5/8 inch profile is commonly used. Solid channels provide higher load capacity, while slotted channels offer more adjustability. Always consult manufacturer load tables and section properties to confirm your choice.

When combining aluminum channels with fasteners or accessories made from stainless steel, galvanized steel, or zinc-plated materials, always use isolating washers, dielectric pads, or polymer-coated hardware to prevent galvanic corrosion. Proper drainage, sealants, and regular inspection further extend system life, especially in harsh or marine environments.

Aluminum unistrut typically supports about one-third the load of an equivalent steel channel due to differences in material strength and stiffness. While suitable for most light and medium-duty applications, always verify span and load limits using published tables and consider steel for heavy-duty or long-span projects.

For custom extrusions, engineered profiles, or large-volume orders, manufacturers like Shengxin in China provide tailored solutions, including OEM brackets and a range of finishes. For urgent or small-run needs, local distributors and suppliers can offer standard profiles with shorter lead times.

dịch vụ trực tuyến

dịch vụ trực tuyến 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360