Have you ever wondered why aluminum is everywhere—from soda cans to airplanes? The answer often comes down to a single property: its melting temperature. The melting temp of aluminum is a defining characteristic that shapes how this metal is used, recycled, and engineered across industries.

Let’s start with the basics. Pure aluminum melts at approximately 660.3°C (1220.5°F) (AZoM). This temperature marks the point where solid aluminum transitions to a liquid state, enabling processes like casting, extrusion, and recycling. But what makes this number so significant?

Imagine you’re designing a lightweight car or planning to recycle beverage cans. Knowing the aluminum melting point helps you:

Aluminum’s relatively low melting temperature also means it can be recycled repeatedly without losing quality. In fact, recycling aluminum uses only about 5% of the energy required to produce new aluminum from ore, highlighting its role in sustainable manufacturing.

This article will dig deeper into:

By the end, you’ll understand why the melting temp of aluminum is more than just a number—it’s a gateway to innovation, efficiency, and sustainability in modern industry.

Ever wondered what really happens when aluminum melts? Picture this: you’re heating a block of aluminum, and, at first, it just gets hotter. But then, something remarkable occurs—a complete transformation known as a phase change. Let’s break down the science behind this process and why it matters for engineers and manufacturers alike.

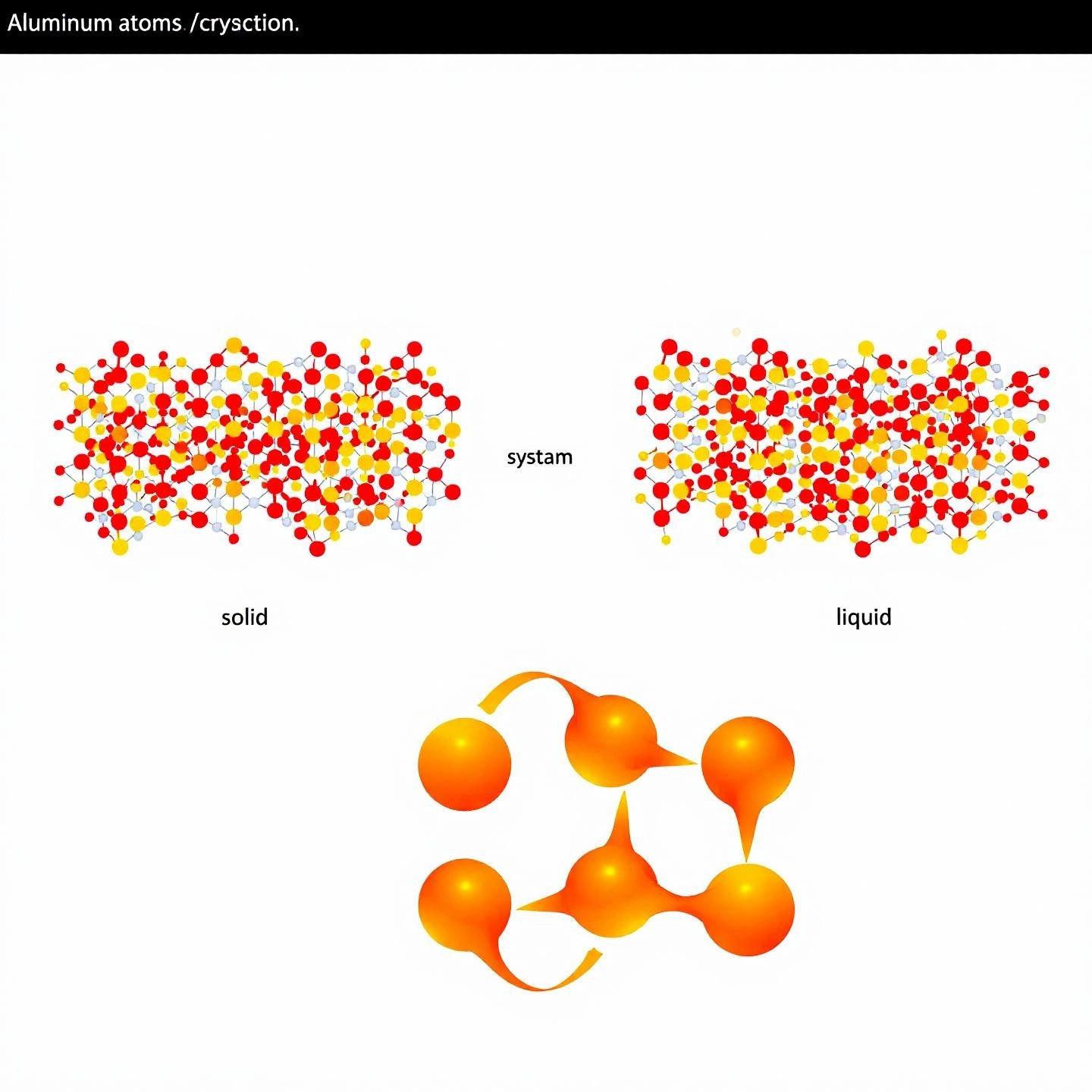

When you apply heat to a solid piece of aluminum, its atoms—arranged in an orderly, crystalline structure—begin to vibrate more rapidly. At lower temperatures, these vibrations aren’t enough to disrupt the strong metallic bonds holding the atoms together. However, as you continue to increase the temperature, the vibrations grow more intense. At 660.3°C (1220.5°F), the critical threshold is reached: the vibrations become so energetic that they break the metallic bonds, causing the rigid structure to collapse and the aluminum to flow as a liquid.

Here’s where things get even more interesting. Not only does aluminum need to reach its melting point, but it also requires an extra boost of energy to actually change state. This energy, known as the latent heat of fusion, is the amount of heat needed to convert aluminum from solid to liquid without raising its temperature further.

Sounds complex? In reality, understanding how aluminum transitions from solid to liquid helps manufacturers:

For professionals in the field, mastering these thermal properties unlocks smarter, more sustainable engineering solutions. To see how these concepts translate into real-world innovation, check out this blog here.

Next, let’s explore how pure aluminum’s single melting point compares to the melting ranges found in aluminum alloys—and what that means for industrial applications.

Imagine you’re heating a piece of pure aluminum—it melts cleanly at a single, well-defined temperature. But what if you’re working with an aluminum ladder, bicycle frame, or aircraft part? In these cases, you’re likely dealing with an aluminum alloy—and the melting story gets a bit more complex. Let’s break down the difference between pure aluminum’s single melting point and the melting range seen in its alloys, and why this matters for manufacturing and engineering.

When you add other elements to aluminum—like copper, magnesium, silicon, or zinc—you create an alloy. These added elements don’t just change the metal’s strength or corrosion resistance; they also affect how it melts. Unlike pure aluminum, which melts sharply at 660°C (1220°F), aluminum alloys usually melt over a range of temperatures. This phenomenon is known as melting point depression and is caused by the way different atoms disrupt aluminum’s crystal structure, making it harder for the metal to transition from solid to liquid in one smooth step.

For example, adding silicon can lower the starting melt point and improve castability. Magnesium and zinc can boost strength but also influence the melting behavior, which is crucial for welding, casting, and forming processes.

To see the differences at a glance, check out the table below. It compares the melting point of pure aluminum with the melting ranges of several common wrought and cast alloys, along with their primary alloying elements:

| Material / Alloy Series | Primary Alloying Element(s) | Melting Range (°C) | Melting Range (°F) |

|---|---|---|---|

| Pure Aluminum (1xxx) | None (Al ≥ 99%) | 660 | 1220 |

| 2xxx (Al-Cu) | Copper | 502 – 638 | 936 – 1180 |

| 3xxx (Al-Mn) | Manganese | 630 – 655 | 1166 – 1211 |

| 4xxx (Al-Si) | Silicon | 577 – 632 | 1071 – 1170 |

| 5xxx (Al-Mg) | Magnesium | 570 – 650 | 1058 – 1202 |

| 6xxx (Al-Mg-Si) | Magnesium & Silicon | 582 – 652 | 1079 – 1206 |

| 7xxx (Al-Zn) | Zinc | 490 – 635 | 914 – 1175 |

Note: Melting ranges are approximate. Pure aluminum has a fixed melting point, while alloys melt within a range depending on composition.

When you’re choosing materials for a project, understanding the aluminum alloy melting point helps you:

For instance, if you’re manufacturing automotive parts that require both strength and formability, a 6xxx series alloy might be ideal due to its balanced melting range and mechanical properties. On the other hand, if you need a material that flows easily into a mold, you might select a 4xxx series alloy with higher silicon content for its lower melting range and improved castability.

Understanding the melting point of aluminum alloys is key to smart material selection and process control. Next, we’ll look at the specific factors—like impurities and pressure—that can further influence these melting temperatures in real-world applications.

When you picture aluminum melting in a foundry or workshop, you might assume the process is always the same. But in reality, several key factors can shift the melting point—sometimes by dozens of degrees. Wondering what causes these changes? Let’s break down the factors affecting aluminum melting point and why they matter in real-world manufacturing.

Did you know that pure aluminum melts at a sharp 660°C (1220°F), but alloys can melt at much lower or higher temperatures? The reason lies in what’s mixed with the aluminum. When elements like copper, magnesium, silicon, or zinc are added, they disrupt the metal’s crystal structure, creating new compounds and phases with different melting behaviors.

Choosing the right alloy composition is crucial for matching the melting behavior to the intended process—whether it’s welding, extrusion, or die casting.

Imagine you’re melting commercial-grade aluminum, not ultra-pure lab samples. Tiny amounts of impurities—like iron, silicon, or copper—can noticeably alter the melting point:

Why does this matter? Inconsistent impurity levels can lead to unpredictable melting behavior, which is a risk for quality control in casting, welding, and forming processes.

It might sound surprising, but pressure also plays a role in the melting point of aluminum:

While pressure effects are usually small in day-to-day manufacturing, they become important when precision is critical or when working in non-standard environments.

Understanding these factors affecting aluminum melting point empowers manufacturers to optimize efficiency and quality. Next, we’ll see how this knowledge translates into real-world processes like casting, extrusion, and welding, where precise temperature control makes all the difference.

Ever wondered why aluminum is the go-to metal for everything from car frames to window profiles? The answer often comes down to its unique melting temperature and how that property shapes real-world manufacturing. Let’s explore how the melting temp of aluminum unlocks efficiency, flexibility, and sustainability in major industrial processes.

Imagine running a foundry or an extrusion plant. The temperature at which aluminum melts—around 660°C (1220°F)—is much lower than that of steel or copper. This seemingly simple fact has powerful implications:

Let’s break down how this property shapes the most important aluminum manufacturing processes:

Did you know recycling aluminum saves up to 95% of the energy needed to produce new metal from ore? Because the melting temp of aluminum is relatively low, remelting scrap consumes far less energy and produces fewer emissions. This is why nearly 75% of all aluminum ever produced is still in use today—making it one of the world’s most sustainable metals.

Sounds simple? In reality, maintaining the right temperature at every stage is critical. Even small deviations can lead to defects like incomplete filling in casting, surface flaws in extrusions, or weak welds. That’s why top manufacturers invest in advanced temperature monitoring and control systems to guarantee consistent, high-quality products.

Take Shengxin Aluminum, for instance. By leveraging deep knowledge of aluminum’s thermal behavior, they produce advanced extruded profiles for industries ranging from construction to rail transit and new energy vehicles. Their expertise in fine-tuning process temperatures ensures each profile meets stringent performance and quality standards—demonstrating how mastering the science translates to real-world success.

So, the next time you see an aluminum window frame or a sleek train carriage, remember: it’s the precise control of the aluminum casting temperature and aluminum extrusion process that makes these innovations possible. Up next, we’ll explore how the melting temperature of aluminum is measured with scientific precision—ensuring consistency and reliability in every application.

When you need to know the exact point at which aluminum shifts from solid to liquid, how do you find out? Measuring aluminum melting point isn’t as simple as watching metal drip in a furnace. In industry and research, precision matters—tiny differences can mean the difference between a flawless product and a costly failure. Let’s demystify the main methods for aluminum melting point testing and see how they ensure quality and consistency in everything from aerospace parts to beverage cans.

Imagine you’re an engineer needing to certify the melting range of a new aluminum alloy. Which tools do you reach for? Here are the primary scientific methods used today—each with its own strengths and ideal applications:

Think about this: a small shift in melting temperature can change how an alloy behaves in a high-stakes application—like a jet engine blade or a car chassis. Accurate aluminum melting point testing helps:

By understanding and applying these scientific methods, engineers and manufacturers can guarantee that every batch of aluminum meets the rigorous demands of modern industry. Next, we’ll see how these precise measurements guide the selection of high-performance alloys for cutting-edge applications in aerospace, automotive, and beyond.

When you see a jet soaring overhead or a sleek electric car gliding down the road, have you ever wondered what makes these machines so light, strong, and reliable? The secret often lies in the careful selection of high performance aluminum alloys—engineered to deliver the right balance of strength, weight, and thermal properties. But how does the melting temp of aluminum factor into these advanced applications? Let’s break it down with real-world scenarios and expert insights.

Imagine the demands placed on an airplane wing or a car’s battery cooling system. These components must withstand high stresses, rapid temperature changes, and harsh environments—all without failing. That’s where the melting point and thermal behavior of aluminum alloys come into play:

Not all aluminum alloys are created equal. In fact, engineers carefully select specific grades based on their unique melting ranges and thermal properties to match the demands of each application. Here’s how this plays out in practice:

Thermal management isn’t just a buzzword—it’s a fundamental design challenge in aluminum in aerospace and automotive sectors. Imagine the heat generated by a car’s battery pack or an aircraft’s avionics bay. Aluminum’s ability to conduct heat away from sensitive components, while staying stable near its melting range, is a key reason it’s used in:

Using advanced alloys, manufacturers can design lighter, more efficient thermal management systems that improve performance and extend the lifespan of critical equipment.

Leading manufacturers like Shengxin Aluminum are at the forefront of applying this knowledge. By mastering the relationship between alloy composition, melting behavior, and thermal performance, Shengxin delivers specialized extruded profiles for sectors such as rail transit and new energy vehicles. Their expertise ensures that every profile meets the stringent requirements for strength, precision, and thermal stability—helping engineers build safer, lighter, and more efficient transportation systems.

In summary, understanding and leveraging the melting temp of aluminum isn’t just a technical detail—it’s the foundation for success in high-performance industries. Next, we’ll wrap up with a summary of key takeaways and explore how ongoing innovation keeps aluminum at the heart of modern engineering.

When you reflect on the journey from a raw aluminum ingot to a finished jet wing or soda can, it’s clear that the melting temp of aluminum is more than just a scientific number—it’s the foundation of modern manufacturing and sustainable engineering. So, what are the big takeaways from our deep dive into this essential property?

Imagine a future where every new building, vehicle, or gadget is lighter, stronger, and more sustainable—aluminum’s unique melting temp makes this vision possible. As the industry continues to innovate, the demand for high-performance, eco-friendly aluminum solutions will only grow.

For those seeking to harness the full potential of aluminum, partnering with forward-thinking manufacturers is key. Companies like Shengxin Aluminum are leading the way, combining technical expertise with a commitment to quality and sustainability in every profile they produce.

Whether you’re designing the next generation of electric vehicles or looking to build greener infrastructure, understanding the melting temp of aluminum is your gateway to smarter, more sustainable engineering. Ready to explore what’s possible? Dive deeper into innovative aluminum solutions and help shape a brighter, more efficient future.

Pure aluminum melts at about 660.3°C (1220.5°F). This relatively low melting temperature is one reason aluminum is widely used and energy-efficient to process in various industries.

Aluminum alloys melt over a range of temperatures, often lower than pure aluminum, due to added elements like copper, magnesium, or silicon. The melting range depends on the specific alloy composition and is essential for selecting materials for casting, extrusion, and high-performance applications.

Aluminum's melting temperature determines how it is cast, extruded, and welded. Its low melting point reduces energy costs, supports recycling, and enables precise control during manufacturing, resulting in high-quality, sustainable products.

The melting temperature can be altered by alloy composition, impurities, and external pressure. Each factor affects how and when aluminum melts, which is critical for quality control and process optimization in industrial settings.

Techniques like Differential Scanning Calorimetry (DSC), Differential Thermal Analysis (DTA), and pyrometry are used to measure aluminum's melting point. These methods ensure precise temperature control and consistent quality in manufacturing and research.

dịch vụ trực tuyến

dịch vụ trực tuyến 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360