Ever struggled to get that perfect, straight line when building, tiling, or woodworking? Or maybe you’ve wondered how professionals achieve those flawless finishes and seamless joints. The answer often comes down to one foundational tool: the aluminum straight edge.

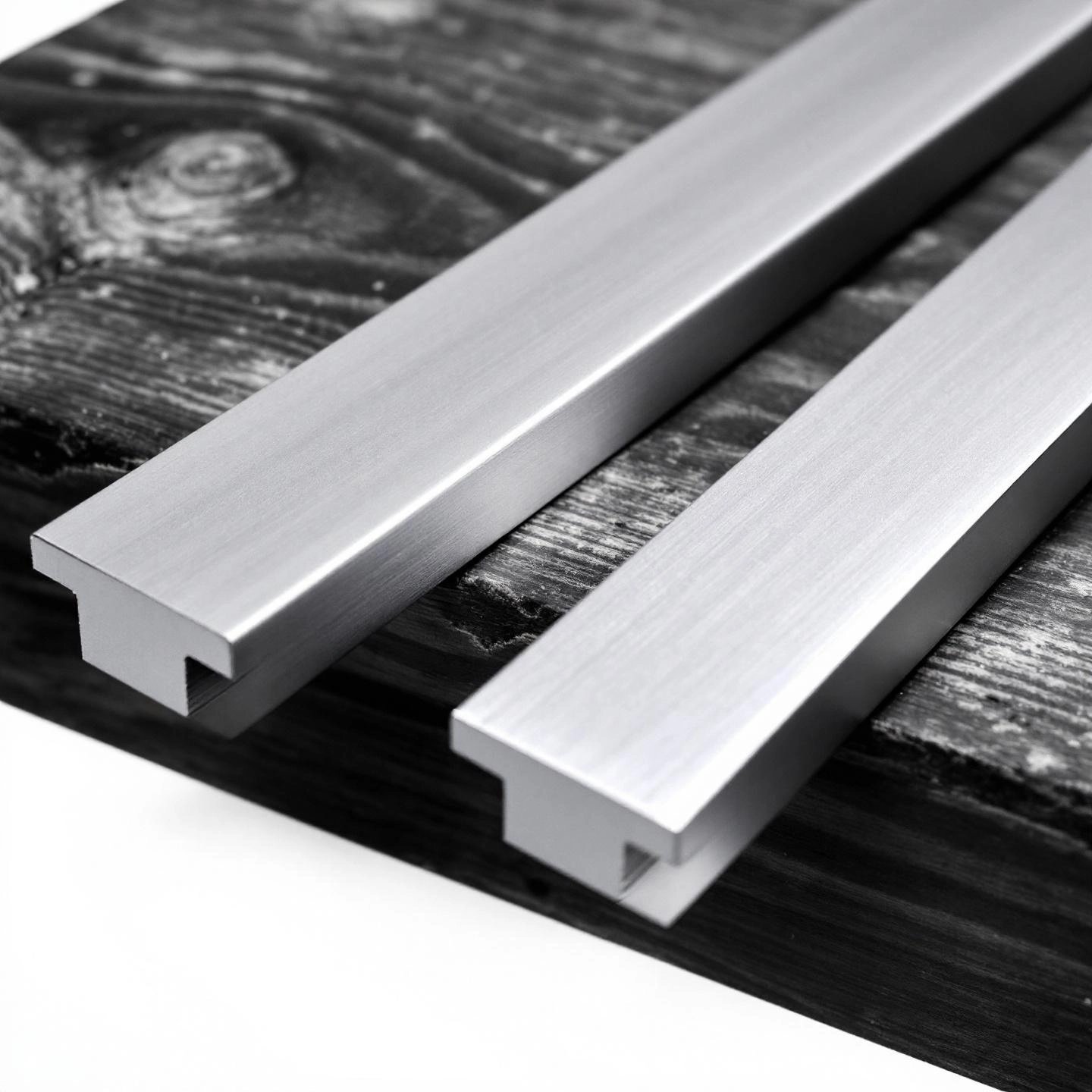

So, what exactly is an aluminum straight edge? Imagine a rigid, lightweight bar made from high-quality aluminum, engineered to be perfectly straight along its entire length. This tool is designed to check flatness, mark precise lines, and guide accurate cuts—making it indispensable for anyone who values precision in their work. Whether you’re a seasoned contractor, a DIY enthusiast, or a hobbyist, you’ll notice that this simple tool can elevate the quality of your projects across many trades.

Let’s break it down by trade and application. Here are just a few ways professionals and DIYers use this tool:

Why aluminum? Unlike steel, aluminum offers a unique combination of lightness and rigidity, which means you can handle even longer straight edges with ease and less fatigue. Its resistance to warping and corrosion ensures reliable accuracy over time, even in tough job site conditions.

With so many options and features available, choosing the right aluminum straight edge tool can feel overwhelming. This article is designed to be your go-to resource—breaking down everything from material benefits and length selection, to practical usage tips and industry-specific advice. Our goal is to empower you with the knowledge you need to select, use, and maintain your straight edge for professional-quality results, no matter your project or skill level.

Ready to unlock a new level of accuracy in your work? Let’s dive into the world of aluminum straight edges and discover how this tool can transform your craftsmanship.

When it comes to selecting a straight edge for your workshop or job site, the decision often boils down to two main materials: aluminum and steel. But which one truly fits your needs? Imagine you’re facing a large-scale tiling project or have to move your tools from site to site—would you prefer a tool that’s light and easy to maneuver, or one that’s heavier and potentially more cumbersome?

| Feature | Aluminum Straight Edge | Steel Straight Edge |

|---|---|---|

| Weight | Lightweight; easy to carry, even in longer lengths | Heavier; can cause fatigue during extended use |

| Corrosion Resistance | Highly resistant to rust and corrosion | Prone to rust unless stainless steel; may require extra care |

| Cost | Generally more affordable for similar precision | Often more expensive, especially for high-grade steel |

| Handling | Easy to maneuver, ideal for frequent relocation | Heavier weight can be awkward, especially in longer sizes |

| Rigidity | Rigid and stable for most applications; may dent if dropped | Very rigid; can also dent or bend under impact |

| Durability | Durable with proper care; resistant to warping | Extremely tough, but heavy and may warp if not handled carefully |

For most professionals and DIYers, the aluminum straight edge benefits are hard to overlook. You’ll notice that its lightweight design makes it perfect for large projects or repeated use—no more arm fatigue after a day of leveling concrete or marking long cuts. Aluminum’s natural resistance to corrosion means you can use it in damp or outdoor environments without worrying about rust, unlike many steel alternatives. Plus, its affordability allows you to invest in multiple lengths or replace a damaged tool without breaking the bank.

Ultimately, if your priority is a balance of precision, ease of use, and long-term value, aluminum stands out as the go-to material for straight edges in most professional settings. Next, let’s see how this lightweight tool delivers flawless results in demanding tasks like concrete finishing.

Ever wondered how professionals achieve that flawless, level look on concrete patios, driveways, or commercial slabs? The secret often lies in the right technique—and the right tool. An aluminum concrete straight edge is essential for screeding, a process that ensures your concrete surface is as flat and true as possible. Whether you’re a seasoned contractor or tackling your first slab, mastering this tool can make all the difference in your results.

Let’s break down the process into manageable steps. Imagine you’ve just poured fresh concrete and want a smooth, professional finish. Here’s how to use an aluminum straight edge for concrete:

While a standard aluminum straight edge works well for most jobs, demanding projects often benefit from a feather edge profile. These tools, such as those engineered by Shengxin Aluminum, feature a tapered, ergonomic shape that makes them exceptionally easy to maneuver over large surfaces. The lightweight yet robust 6063-T5 aluminum alloy construction ensures minimal flex and precise alignment, even on expansive pours.

Imagine finishing a commercial slab or a large driveway—using a professional-grade aluminum feather edge not only speeds up the process but also delivers a surface that’s ready for finishing with minimal touch-up.

With the right technique and a quality aluminum screed, you’ll achieve a perfectly flat, durable concrete surface—ready for finishing or decorative work. Next, let’s see how the same tool brings precision to tile installation, ensuring flawless grout lines and level surfaces.

Ever laid out a row of tiles, only to step back and notice uneven grout lines or subtle dips in the floor? When it comes to tiling, even the smallest misalignment can throw off the entire look of a room. That’s where a precise aluminum straight edge for tile work becomes essential—helping you create crisp, level, and professional results every time.

Imagine investing hours in a beautiful tile job, only to realize the grout lines wander or some tiles sit higher than others. Not only does this affect the aesthetics, but it can also lead to long-term durability issues. Using an aluminum straight edge for tiling helps you prevent these problems by providing a reliable reference for every stage of installation.

Let’s break down exactly how this tool elevates your tile work. Here’s how professionals and savvy DIYers put it to use:

Let’s say you’re tiling a bathroom wall that’s been waterproofed (tanked). You can’t screw a batten into the wall, so you rest your aluminum straight edge on stands or spacers to create a perfectly level base for your first row. This method is favored by many pros because it eliminates reliance on potentially warped timber and allows for quick repositioning as you work.

The difference between a DIY look and a professional finish often comes down to the tools you use. With a precision-milled, lightweight straight edge, you can:

In summary, whether you’re tackling a kitchen backsplash or a large-format tile floor, incorporating an aluminum straight edge for tiling into your workflow ensures every tile sits perfectly in place. Next, discover how this same tool becomes your best ally for guiding straight, clean cuts in woodworking and beyond.

Ever found yourself struggling to make a perfectly straight cut with a circular saw or utility knife? Or maybe you’ve tried following a pencil line, only to end up with a wavy edge and wasted material. Sounds familiar? This is where an aluminum straight edge cutting guide truly shines—transforming your workflow from trial and error to precision and confidence.

Imagine you want to cut a large plywood sheet for a cabinet, but your table saw just isn’t big enough. By using a robust, thick-profile aluminum straight edge as a guide, you can achieve factory-straight cuts with handheld tools. The principle is simple: clamp the straight edge securely to your workpiece, and let it act as a fence for your saw, router, or knife. This method is not only effective in woodworking but also invaluable for drywall, plastics, and even sheet metal.

Not all guides are created equal. A robust, thick-profile aluminum straight edge resists flexing or bowing, which is crucial for both safety and accuracy. Thin or lightweight edges may bend under clamp pressure or tool movement, leading to crooked cuts and potential hazards. Professional-grade guides often feature extruded aluminum construction for maximum rigidity and durability.

Imagine building a custom bookcase: with an aluminum straight edge for woodworking, you can cut every panel to the exact dimension, ensuring tight joints and a professional finish—even if you’re working in a small garage shop.

Ready to tackle your next project with confidence? With the right aluminum straight edge cutting guide, you’ll achieve straight, clean cuts—no table saw required. Next, we’ll explore how to pick the perfect straight edge length for every task, ensuring you’re always prepared, from small repairs to large-scale builds.

Ever wondered why your results sometimes fall short, even when you’re using a quality straight edge? The answer might be as simple as using the wrong length for the job. When it comes to selecting the ideal tool, size truly does matter—too short, and you risk missing subtle dips or humps; too long, and handling becomes awkward or impractical. So, how do you pick the perfect length for your needs?

Let’s break it down by project type and popular size options. Imagine you’re setting up your workshop, planning a tiling job, or prepping for a major concrete pour. Here’s how to match your straight edge to the task for maximum precision and efficiency:

Imagine trying to level a 12-foot concrete slab with a 3-foot straight edge—you’d have to move and reposition constantly, increasing the chances of inconsistencies. Conversely, using a 12-foot tool for a 2-foot cabinet door is unwieldy and unnecessary. As discussed by experienced machinists and builders, it’s best to choose a straight edge that closely matches the length of the surface you’re working on. This approach minimizes time, effort, and potential for error.

Choosing the right length straight edge is about matching the tool to the job—ensuring accuracy, efficiency, and ease of use in every project. Up next, we’ll dive deeper into the differences between extruded and anodized aluminum straight edges, helping you select the best finish and profile for your professional needs.

When choosing a straight edge for professional or DIY projects, you’ll often encounter two terms: extruded aluminum and anodized aluminum. But what do these really mean, and which is right for your needs? Let’s break down the differences so you can make an informed decision—and see why leading manufacturers like Shengxin Aluminum focus on both processes to deliver top-tier performance.

Imagine you’re shaping clay through a mold to create a perfectly straight bar—that’s a lot like the aluminum extrusion process. Here, heated aluminum alloy is forced through a die to form a straight, rigid profile with precise dimensions. This method ensures your straight edge is consistently flat, stable, and true along its entire length.

Now, think about adding a protective, beautiful finish to that bar. Anodizing is an advanced electrochemical process that builds a thick, durable oxide layer on the aluminum’s surface. This layer isn’t just for looks—it dramatically boosts corrosion resistance, wear protection, and even scratch resistance, making your tool last longer, even in tough environments.

| Feature | Extruded Aluminum Straight Edge | Anodized Aluminum Straight Edge |

|---|---|---|

| Manufacturing Process | Formed by pushing aluminum through a die for precise, consistent shape | Extruded, then treated with an electrochemical process to add a thick oxide layer |

| Surface Finish | Raw (mill finish); may show minor die marks or discoloration | Smooth, uniform, attractive finish; available in clear or colored options |

| Corrosion Resistance | Good (natural oxide layer forms), but limited in harsh or wet conditions | Excellent; thick anodic layer protects against rust, chemicals, and abrasion |

| Durability | Rigid and strong, but more prone to surface scratches or wear over time | Highly resistant to scratches, nicks, and everyday wear; ideal for frequent use |

| Maintenance | May require more care to prevent surface damage; less forgiving of rough handling | Easy to clean; resists staining and maintains appearance longer |

| Cost | Generally more economical | Higher initial investment, but longer lifespan and better value over time |

| Best For | Dry, indoor environments; budget projects; less visible applications | Demanding jobsites; outdoor or wet environments; professional results |

If you’re working in environments where moisture, abrasion, or regular handling are part of the job, an anodized aluminum straight edge is a smart upgrade. The anodic layer—up to 50,000 times thicker than the natural oxide on raw aluminum—acts like a shield against corrosion, scratches, and even most chemical exposures. Plus, the finish stays looking new, even after years of use.

Imagine a tool that’s not only straight and rigid but also built to withstand years of tough jobsite conditions. That’s why top manufacturers like Shengxin Aluminum combine precision extrusion with a professional-grade anodized finish. Their feather edge profiles, for example, are engineered from high-strength 6063-T5 aluminum, then anodized for maximum protection and longevity. This dual-process approach ensures you get a straight edge that stays accurate, resists damage, and looks professional no matter how demanding your work gets.

In summary, when you’re choosing between an extruded aluminum straight edge and an anodized aluminum straight edge, consider where and how you’ll use it. For the ultimate in durability, appearance, and ease of maintenance, anodized models are the clear winner—especially when sourced from manufacturers who prioritize both material quality and finishing excellence. Up next, we’ll guide you through the essential features to look for in a woodworking straight edge, so you can maximize precision in your next project.

When you’re setting up machinery, checking panel flatness, or marking precise layouts in your workshop, the right straight edge can make all the difference. But with so many options available, how do you know which features truly matter for aluminum straight edge woodworking? Imagine trying to align your jointer beds or set up a table saw—would you trust a tool that’s not perfectly straight or comfortable to use?

To help you choose the best aluminum straight edge ruler for your woodworking projects, here’s a practical checklist of must-have features—and why each one matters:

| Feature | Why It Matters in Woodworking |

|---|---|

| Certified Flatness | Ensures absolute accuracy when checking surfaces, setting up machines, or aligning components. For example, a high-quality straight edge is machined flat to within 0.003" over its length, providing the confidence needed for fine-tuning jointers and planers. |

| Rigid Profile | Prevents flexing or bowing under its own weight or during use. A rigid aluminum profile stands upright without support, making it easier to check for flatness and mark straight lines on large panels or tables. |

| Clear Etched Markings | Permanent, easy-to-read graduations (inches, fractions, or metric) simplify layout work and measurement—no more squinting or guessing. Some models offer customizable adhesive-backed rules for added versatility. |

| Ergonomic Grip | Comfortable handling is crucial during repetitive tasks. Rounded or contoured edges reduce fatigue and improve control when maneuvering the straight edge across large surfaces. |

| Hanging Hole for Storage | Allows for safe, convenient storage on a nail or hook—keeping your straight edge straight and within easy reach, and reducing the risk of accidental damage. |

Imagine setting up your planer or marking out cabinet panels—each of these features streamlines the process and helps you achieve the professional results you expect. For those who work across multiple disciplines, these same qualities make an aluminum straight edge ruler a versatile addition to any shop.

Next, we’ll explore when it makes sense to invest in a straight edge set versus individual tools, so you can equip your workspace for maximum efficiency and flexibility.

Ever found yourself wishing you had a longer straight edge for that concrete slab, or a shorter one for a quick machine setup? Imagine you’re halfway through a project and realize your single tool just isn’t the right fit—frustrating, right? That’s where investing in an aluminum straight edge set can truly transform your workflow, offering unmatched flexibility and efficiency across a wide range of tasks.

While a single straight edge might be enough for occasional use or very specific jobs, most professionals and dedicated DIYers quickly discover the benefits of having a set. Here’s why:

"A straight edge tool is more than just a simple accessory; it’s a cornerstone of precision in woodworking. By investing in a high-quality straight edge tool and utilizing it effectively, you can significantly enhance your craftsmanship, improve safety, and streamline your workflow."

There’s no one-size-fits-all answer, but most experts recommend at least two to three different lengths—short (2–4 ft), medium (6–8 ft), and long (10–12 ft)—to cover the majority of professional and DIY applications. This approach ensures you’re never caught off guard by a new project or challenging measurement.

Imagine the convenience of having every size at your fingertips: you’ll work faster, more accurately, and with far less stress. Next, we’ll wrap up with a summary of the aluminum straight edge’s core advantages and how choosing the right tool set is an investment in lasting precision and efficiency.

Ever notice how the smallest details can make or break your project’s outcome? Whether you’re a pro on the jobsite or a dedicated DIYer, the choice of your straight edge tool is one of those details that quietly determines the quality of your results. So, what have we learned about the aluminum straight edge for professionals and why does it matter so much?

Throughout this guide, we’ve seen how an aluminum straight edge is more than just a measuring stick—it’s a precision instrument that empowers you to:

Imagine tackling a new build, a tile renovation, or a custom furniture piece—having a precision aluminum straight edge at your side means every line, edge, and surface can meet the highest standards of accuracy and finish.

So, how do you choose the right tool? The key is to match your straight edge to the demands of your work. Here’s a recap of essential selection points:

| Criteria | Why It Matters |

|---|---|

| Certified Straightness | Ensures reliable, repeatable accuracy—crucial for professional results |

| Material & Finish | High-strength, lightweight aluminum with an anodized finish resists corrosion and wear |

| Profile & Rigidity | Robust, ergonomic profiles reduce flex and user fatigue, especially on large jobs |

| Length Options | Multiple sizes allow you to tackle everything from fine joinery to expansive concrete pours |

| Ease of Handling | Lightweight construction and thoughtful design make setup and transport easy |

Choosing a straight edge isn’t just about the specs—it’s about investing in a tool that will deliver consistent, professional-quality results for years to come.

When you select a precision aluminum straight edge, you’re not just buying a tool—you’re investing in your own accuracy, efficiency, and reputation. The right straight edge minimizes costly rework, reduces setup time, and ensures every project meets your highest standards. Imagine the confidence of knowing your surfaces are flat, your cuts are true, and your finishes are flawless—every single time.

For those who demand the best, consider exploring advanced options like Shengxin’s Aluminum Feather Edge. These tools are engineered for the toughest environments, combining:

These features directly address the needs of professionals and serious DIYers—guaranteeing a tool that’s not only accurate, but also comfortable and resilient enough for daily, demanding use.

“A straight edge tool is more than just a simple accessory; it’s a cornerstone of precision in woodworking. By investing in a high-quality straight edge tool and utilizing it effectively, you can significantly enhance your craftsmanship, improve safety, and streamline your workflow.”

In summary, choosing the right aluminum straight edge is a strategic investment in your craft—delivering the accuracy, efficiency, and reliability that set your work apart. Whether you’re leveling concrete, aligning tile, or fine-tuning joinery, a professional-grade straight edge is the silent partner behind every flawless result. Ready to elevate your projects? Make precision your standard with the best tool for the job.

Aluminum straight edges are significantly lighter, making them easier to handle for large or repetitive jobs. They resist corrosion, are generally more affordable, and are easier to transport compared to steel. This makes them ideal for professionals who need a reliable, long-lasting, and efficient tool for accurate measurements and leveling.

Select your straight edge length based on the project: short lengths (2–4 ft) are best for small or detailed work, medium lengths (6–8 ft) suit general carpentry and panel work, and long lengths (10–16 ft) are ideal for concrete screeding or large surfaces. Having a set with multiple sizes ensures you're prepared for any task.

Extruded aluminum straight edges are shaped for consistent rigidity and precision, while anodized versions have a protective finish that enhances corrosion and wear resistance. Anodized straight edges are preferred for demanding or outdoor environments due to their durability and easy maintenance.

Yes, aluminum straight edges are excellent cutting guides for circular saws, routers, and utility knives. Their rigid, straight profile ensures clean, accurate cuts when clamped securely, making them invaluable for woodworking, drywall, and sheet material projects.

Shengxin’s Aluminum Feather Edge offers high-strength, lightweight construction with a corrosion-resistant anodized finish and certified straightness. Its ergonomic, tapered profile reduces fatigue and ensures precise results, making it an excellent investment for tradespeople demanding accuracy and durability.

dịch vụ trực tuyến

dịch vụ trực tuyến 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360