Ever wondered why 6061 aluminum is the go-to choice for so many engineers, designers, and manufacturers? Imagine a single alloy that can be machined into bike frames, welded into aircraft parts, or extruded into architectural beams—all while offering a balance of strength, workability, and corrosion resistance. That’s the appeal of 6061 aluminum.

This alloy stands out as a highly versatile, precipitation-hardened material, often referred to as the “workhorse” of the aluminum family. Its secret? The primary alloying elements: magnesium and silicon. In fact, 6061 aluminum is composed of about 97.9% aluminum, with magnesium (1.0%) and silicon (0.6%) playing the leading roles in its unique performance profile. These elements combine to form magnesium silicide during heat treatment, enhancing the material’s strength and overall reliability.

But it doesn’t stop there. 6061 aluminum is also renowned for its:

Because of these qualities, aluminum 6061 is everywhere—from aerospace and automotive components to consumer electronics and construction materials.

Sounds complex? Don’t worry. This guide breaks down everything you need to know about 6061 aluminum alloy in a clear, practical way. Here’s what you’ll discover next:

Whether you’re a designer, engineer, or just curious about modern materials, you’ll find actionable insights and expert knowledge throughout this guide. Let’s dive in and see why 6061 aluminum remains the backbone of so many industries.

When you’re selecting a material for a demanding application, you want hard numbers—facts you can trust. That’s where the 6061 T6 aluminum properties truly shine. The T6 temper is achieved through a carefully controlled heat treatment process, resulting in a material that balances strength, ductility, and workability. But what do these numbers actually look like? Let’s break down the core mechanical metrics that define aluminum 6061 material properties in its most popular temper.

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Density | 2.70 g/cm³ | 0.0975 lb/in³ |

| Ultimate Tensile Strength | 310 MPa | 45,000 psi |

| Yield Strength | 276 MPa | 40,000 psi |

| Elongation at Break (1/16 in. thickness) | 12% | 12% |

| Modulus of Elasticity | 68.9 GPa | 10,000 ksi |

| Fatigue Strength | 96.5 MPa | 14,000 psi |

| Shear Strength | 207 MPa | 30,000 psi |

| Hardness (Brinell) | 95 | 95 |

These values, sourced from industry standards such as ASM and Alcoa, make it clear why 6061-T6 is so widely used in structural and mechanical design (MatWeb).

But there’s more to 6061 aluminum than just strength. Its physical and thermal properties are equally important, especially for applications exposed to temperature changes or requiring electrical conductivity. Here’s a quick overview:

| Property | Value (Metric) | Value (Imperial) |

|---|---|---|

| Thermal Conductivity | 167 W/m·K | 1160 BTU·in/hr·ft²·°F |

| Specific Heat Capacity | 0.896 J/g·°C | 0.214 BTU/lb·°F |

| Coefficient of Thermal Expansion | 23.6 μm/m·°C | 13.1 μin/in·°F |

| Electrical Resistivity | 3.99 × 10-6 Ω·cm | 3.99 × 10-6 Ω·cm |

| Melting Point (Solidus–Liquidus) | 582–652°C | 1080–1205°F |

With a density of 6061 aluminum at 2.70 g/cm³, this alloy offers a high strength-to-weight ratio, making it ideal for aerospace, transportation, and structural applications where every ounce counts.

Imagine you’re building a lightweight bike frame, a marine fitting, or a precision-machined part. You’ll notice that 6061-T6 aluminum delivers a blend of strength, ductility, and thermal stability that’s hard to match. Its mechanical and thermal profile ensures reliable performance in everything from cold-weather environments to high-heat applications—without sacrificing machinability or weldability.

Now that you have a technical snapshot of 6061 t6 aluminum properties, let’s explore how the T6 temper process works and why it transforms this alloy into an engineering favorite.

Ever see “6061-T6 aluminum” on a technical drawing and wonder what the “T6” actually stands for? While it might sound like a simple code, this temper designation is the key to unlocking the alloy’s full potential—transforming standard 6061 aluminum into a material prized for its remarkable strength and reliability. Let’s break down what happens during the T6 tempering process and why it matters for your next project.

Imagine starting with a soft, easily shaped piece of aluminum alloy 6061—this is the “O” or annealed condition. It’s great for forming, but not for applications where strength is critical. To turn this soft material into something tougher, engineers use a two-step heat treatment process. The first step is called solution heat treating:

This step is crucial because it prepares the microstructure of material 6061 T6 aluminum for a dramatic transformation in strength.

After solution heat treatment, the alloy isn’t at its strongest yet. That’s where artificial aging—also known as precipitation hardening—comes in. Here’s how it works:

Think of it like reinforcing concrete with steel rebar: the microstructure is strengthened from within, giving 6061-T6 aluminum its signature performance edge.

The T6 temper can boost 6061 aluminum’s yield strength by over 300% compared to its annealed (O) state, making it suitable for demanding structural and mechanical applications.

The main takeaway? The T6 temper transforms 6061-t6 aluminum from a material that’s easy to form into one that’s tough, resilient, and ready for high-stress environments. This is why you’ll find it in everything from aircraft parts to automotive components—places where both light weight and strength are non-negotiable.

Understanding the science behind the T6 temper helps you select the right aluminum for your needs, ensuring you get the perfect balance of workability and performance. Next, we’ll take a closer look at the specific strength and elasticity numbers that make 6061-T6 a favorite among engineers.

When you’re designing anything from a bike frame to a bridge truss, knowing how much force your material can take before it bends or breaks is essential. That’s where two critical metrics—yield strength and ultimate tensile strength—come into play for 6061 aluminum.

Yield strength is the maximum stress that 6061-T6 aluminum can withstand while still returning to its original shape once the load is removed. If you push the material past this point, it will deform permanently. For 6061 t6 aluminum yield strength, the typical value is 276 MPa (40,000 psi) (MatWeb). This is the number engineers use when calculating how much load a structure can safely carry without permanent deformation.

Ultimate tensile strength is the maximum stress the material can handle before it actually breaks. For 6061-T6, this value is 310 MPa (45,000 psi). Think of yield strength as your warning sign—go past it, and you risk permanent bends. Ultimate strength is the absolute limit before catastrophic failure.

Let’s put these numbers into perspective: Imagine a structural beam made from 6061-T6 aluminum. As long as the applied stress stays below 276 MPa, the beam will flex but return to its original shape. Push it to 310 MPa or beyond, and the beam will snap.

But strength isn’t the whole story. How much will your part bend under a given load? That’s where the modulus of elasticity—also called Young’s modulus—comes in. For 6061-T6 aluminum, the modulus of elasticity is 68.9 GPa (10,000 ksi).

This value measures the material’s stiffness, or its resistance to elastic (temporary) deformation. The higher the modulus, the less a part will stretch, bend, or flex under load. For example, if you build a long-span truss or a precision machine component, you’ll want a material with a predictable modulus so you can calculate exactly how much it will deflect under stress.

When you combine yield strength and modulus of elasticity, you get a full picture of how 6061 aluminum will perform in real-world applications—whether it’s supporting a load, absorbing vibration, or resisting bending forces.

It’s important to know that these properties aren’t set in stone. Several factors can influence the 6061 aluminum yield stress and elasticity in practice:

Understanding these nuances helps engineers design safer, more efficient structures and components. By leveraging the robust 6061 aluminum modulus of elasticity and dependable yield strength, you can confidently predict how your designs will behave under real-world loads. Next, we’ll compare 6061 to other popular alloys so you can choose the best fit for your next project.

Choosing the right aluminum alloy can feel like navigating a maze—especially with so many options on the table. When you’re faced with a decision like aluminum 6061 vs 6063, 5052 aluminum vs 6061, or 6061 aluminum vs 7075 aluminum, it’s important to understand how each alloy stacks up in terms of strength, corrosion resistance, weldability, formability, and cost. Let’s break down these differences so you can select the best fit for your project.

| Property | 6061 | 7075 | 5052 | 6063 |

|---|---|---|---|---|

| Strength | High (Yield ~276 MPa, Tensile ~310 MPa) | Very High (Yield up to 500 MPa, Tensile ~600 MPa) | Moderate (Yield ~130–220 MPa, Tensile ~240–350 MPa) | Medium (Lower than 6061; good for architectural use) |

| Corrosion Resistance | Excellent | Good (requires protection in harsh environments) | Excellent (especially in marine environments) | Excellent |

| Weldability | Very Good | Poor (prone to cracking) | Excellent | Very Good |

| Formability | Good (not ideal for tight bends in T6 temper) | Poor (not recommended for bending) | Excellent (can be bent and shaped easily) | Very Good (ideal for complex extrusions) |

| Cost | Moderate (10–15% more than 5052) | High (premium alloy) | Lowest | Low to Moderate |

| Typical Applications | Structural, aerospace, automotive, bike frames | Aerospace, high-performance sporting goods | Marine, tanks, piping, siding | Architectural extrusions, window/door frames |

Data sourced from industry references and validated by ASM International and MatWeb.

When you compare 7075 aluminum vs 6061, the first thing you’ll notice is the dramatic jump in strength. 7075, with its high zinc content, is a powerhouse—yield strengths can reach up to 500 MPa, making it the material of choice for critical aerospace parts and high-end sporting goods. But this strength comes at a price: 7075 is less weldable, harder to form, and significantly more expensive than 6061. If your project demands maximum strength and you’re willing to invest, 7075 is unbeatable. For most structural and general engineering uses, 6061 offers a much better balance of strength, cost, and ease of fabrication.

Looking at 5052 aluminum vs 6061, the choice often comes down to formability and corrosion resistance. 5052 shines in marine environments thanks to its exceptional corrosion resistance—think boat hulls, tanks, and piping. It’s also the go-to for projects requiring tight bends and easy forming, as it’s much more ductile than 6061. However, 6061 is stronger and better suited for structural applications where load-bearing performance matters. If you need to weld and form complex shapes, 5052 is your friend; if you need strength and machinability, 6061 is the winner.

The aluminum 6061 vs 6063 debate is common in the world of extrusions. Both alloys offer good corrosion resistance and weldability, but their strengths diverge. 6063 is the top pick for architectural applications—its superior surface finish and excellent extrudability make it ideal for window and door frames, railings, and decorative profiles. 6061, on the other hand, is stronger and used for more demanding structural components, such as automotive parts and heavy-duty extrusions. If your project is all about looks and intricate shapes, go with 6063; if you need strength and versatility, 6061 is the better choice.

Still unsure? Here are some quick guidelines to help you decide:

By understanding these key differences, you’ll be able to match the right alloy to your project’s unique demands—whether you’re building for the ocean, the skies, or anywhere in between. Next, let’s get practical with best practices for machining, welding, and fabricating 6061 aluminum in real-world applications.

When it comes to real-world projects, knowing how to work with 6061 aluminum can make or break your results. Whether you’re machining a precision part, welding a frame, or flattening 6061 aluminum tube for a custom build, each fabrication method comes with unique challenges and best practices. Let’s break down what you need to know to get the most from 6061 aluminum sheet, tube, or plate—without the headaches.

Ever struggled with tool wear or poor surface finish when machining 6061-T6? You’re not alone. While this alloy is known for its good machinability, achieving top-quality results requires a thoughtful approach. Here’s how to get it right:

For common operations like face milling, end milling, drilling, and tapping, always use sharp, high-helix carbide tools and proper chip evacuation techniques (such as peck drilling for deep holes). This approach is especially critical when working with thin-walled 6061 aluminum sheet or delicate profiles.

Welding 6061 aluminum is both an art and a science. While the alloy is weldable, it’s prone to hot cracking and porosity if not handled properly. Here’s a step-by-step guide to help you achieve strong, clean welds:

Always prioritize safety: use proper PPE, ensure good ventilation, and keep a fire extinguisher nearby. These steps help ensure reliable, high-quality welds on everything from 6061 aluminum sheet assemblies to complex tubular frames.

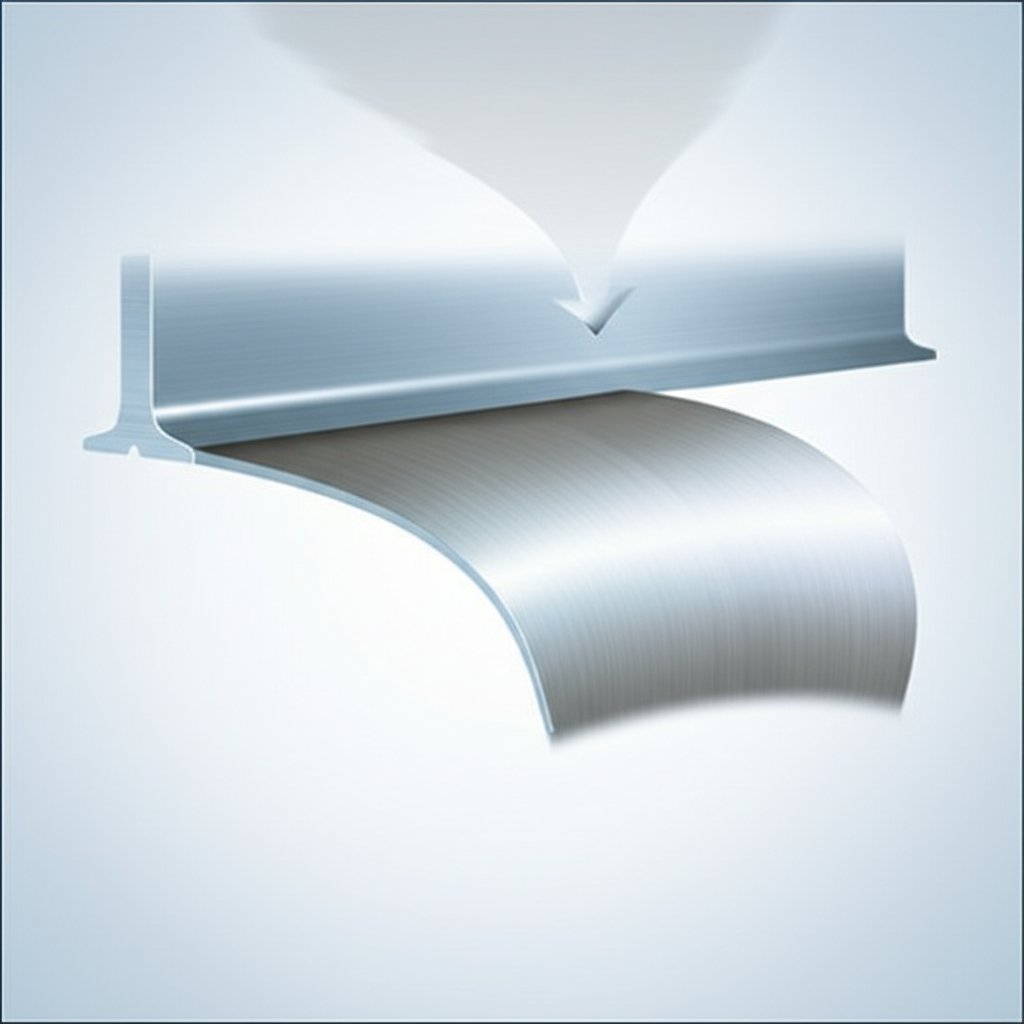

Thinking about flattening 6061 aluminum tube or bending 6061-T6 sheet? Here’s where things get tricky. The T6 temper, while strong, makes the alloy less ductile and more prone to cracking during tight bends.

While 6061 is not the easiest alloy to form, especially in T6 condition, careful planning and the right techniques make it possible to achieve complex shapes and reliable results. For repeated jobs or tight tolerances, consider working with annealed material and tempering after forming.

By mastering these fabrication techniques, you’ll unlock the full potential of 6061 aluminum for your next project—whether you’re machining intricate parts, welding structural assemblies, or forming custom profiles. Up next, we’ll explore how these fabrication strengths translate into real-world applications across industries.

When you think about materials that truly shape our world, 6061 aluminum stands out for its unmatched versatility. But what makes aluminum 6061-t6 the backbone of so many industries? The answer lies in its unique combination of strength, lightweight nature (thanks to a density aluminum 6061 t6 of just 2.70 g/cm³), corrosion resistance, and ease of fabrication. Let’s explore how these qualities translate into real-world solutions, industry by industry.

Imagine designing an aircraft wing or a high-performance car chassis. You need a material that’s strong enough to handle stress, yet light enough to reduce fuel consumption. That’s where 6061-T6 aluminum shines. Its high strength-to-weight ratio and excellent machinability make it ideal for:

Why choose 6061 here? Its ability to be precisely machined and welded means complex, weight-sensitive structures can be produced efficiently, while its resistance to fatigue and corrosion ensures long-term reliability—even under the harshest conditions.

Saltwater, extreme weather, and constant load changes demand materials that won’t quit. 6061 aluminum’s natural oxide layer provides outstanding corrosion resistance, making it a favorite in marine and architectural projects. You’ll find it in:

6061’s adaptability to both extrusion and welding allows architects and engineers to create custom shapes and large-scale structures that last, even in challenging marine or urban environments.

Ever picked up a sleek laptop or a lightweight fishing reel and wondered what makes it feel so solid yet light? The answer is often 6061 aluminum. Its machinability and ability to hold a high-quality finish make it the top pick for:

Manufacturers choose 6061 not just for its technical properties, but because it enables innovative designs, tight machining tolerances, and attractive finishes that consumers expect from high-end products.

From aerospace and automotive breakthroughs to everyday electronics and sporting gear, the applications of 6061 aluminum are as diverse as they are essential. Its unique blend of lightweight strength, corrosion resistance, and workability continues to drive innovation across industries. In the next section, we’ll discuss how to source 6061 aluminum in the right form and quality for your next project—ensuring your designs are built to last.

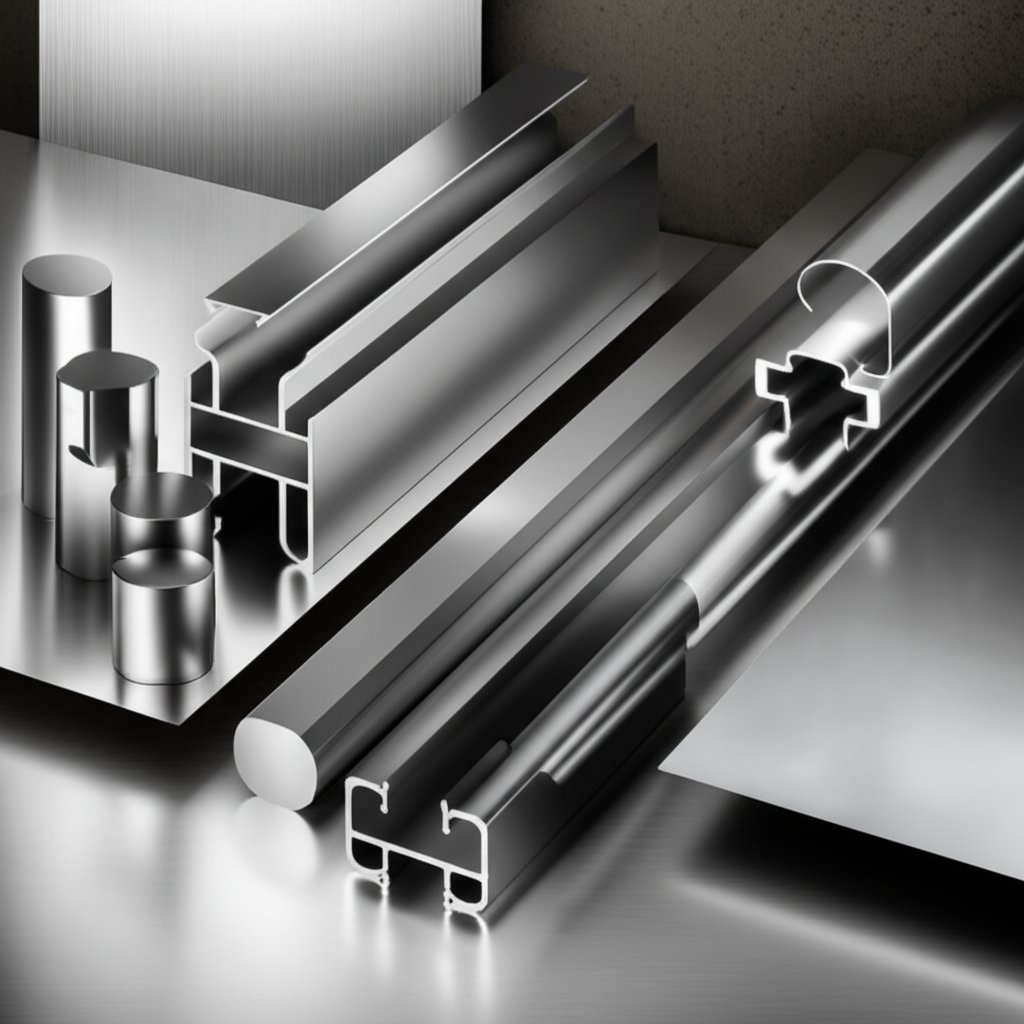

When you’re ready to turn your ideas into reality, sourcing the right form of aluminum 6061 is the first step. But with so many shapes and suppliers on the market, where do you begin? Imagine you’re building a custom machine frame, a lightweight marine part, or a batch of architectural profiles—each project demands a specific form and finish. Here are the most common options you’ll encounter:

Most reputable suppliers offer a range of thicknesses, tempers, and lengths, with custom cutting and finishing services to match your project’s requirements. If you need something unique—like a proprietary extrusion or a tight-tolerance part—ask about custom die design and secondary operations such as anodizing or CNC machining.

Not all suppliers are created equal. The quality of your 6061 aluminum alloy materials will directly impact the performance and reliability of your finished product. So, what should you look for in a supplier?

It’s wise to compare several suppliers, review their business profiles, and request quotes to ensure you’re getting the best combination of quality, price, and service.

For projects demanding precise tolerances and consistent quality in 6061 aluminum profiles, partnering with an experienced manufacturer is critical. Shengxin specializes in custom extrusions, offering engineering support and reliable production for clients worldwide.

Whether you’re sourcing standard bar stock or designing a custom extruded solution, choosing the right supplier sets the foundation for project success. When tolerances are tight and quality is non-negotiable, working with a proven manufacturing partner like Shengxin Aluminum ensures your 6061 aluminum alloy components meet the highest standards—every time.

6061 aluminum is a versatile, precipitation-hardened alloy containing magnesium and silicon. Its balanced strength, corrosion resistance, and excellent machinability make it the preferred choice for diverse applications in aerospace, automotive, marine, and consumer products.

The T6 temper involves solution heat treating and artificial aging, significantly boosting the alloy’s strength and hardness. This process transforms 6061 from a soft, formable state to a high-performance material ideal for structural and load-bearing uses.

6061 offers a strong balance of strength, weldability, and cost. 7075 is much stronger but less weldable and more expensive. 5052 excels in corrosion resistance and formability, making it ideal for marine uses. 6063 is preferred for architectural extrusions due to its superior surface finish and extrudability.

Seek suppliers with quality certifications (like ISO 9001), technical support, a wide range of available forms, and value-added services. For custom extrusions or precise tolerances, partnering with an experienced manufacturer such as Shengxin ensures consistent quality and engineering support.

6061 aluminum is commonly machined, welded, and formed. For best results, use sharp carbide tools, proper coolants, and rigid setups in machining. When welding, clean surfaces thoroughly and select appropriate filler alloys. For bending or forming, consider annealing first to reduce cracking risks.

dịch vụ trực tuyến

dịch vụ trực tuyến 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360