Ever wondered how engineers build custom workstations, machine guards, or even DIY projects without welding or heavy machinery? The answer often lies in a clever system called 8020 aluminum. But what is 8020 aluminum, really? Despite its technical-sounding name, it’s not a specific metal or alloy—instead, it’s a versatile modular T-slot framing system that’s transforming the way people design and build custom structures.

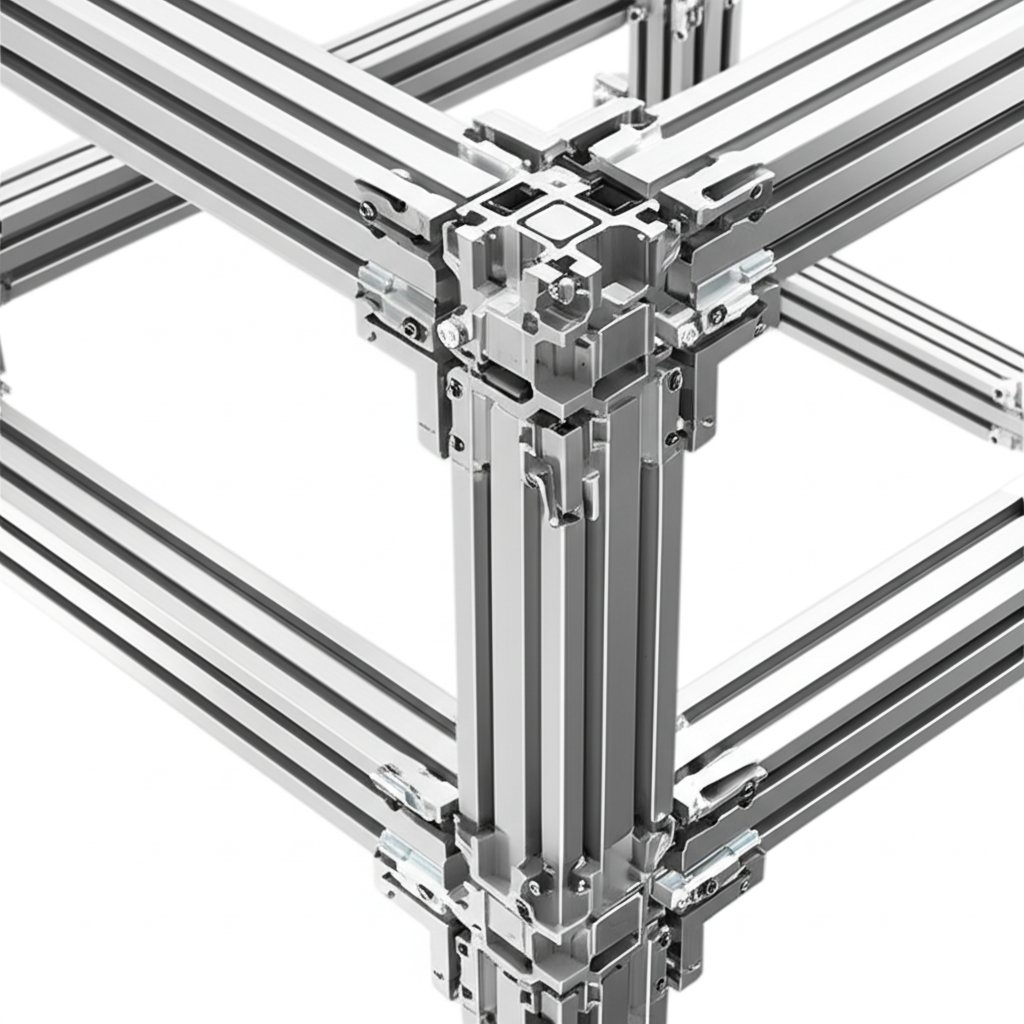

When you first hear the term “8020 aluminum,” you might assume it refers to an alloy or a particular metal blend. In reality, it’s the name of a system invented and patented by the 80/20 company in 1979. The system uses T-slot aluminum extrusions: long, lightweight bars with T-shaped channels running their length. These channels allow you to quickly connect pieces together using specialized brackets and fasteners—no welding, drilling, or heavy tools required. Imagine building with adult-sized, industrial-strength LEGO blocks, but made from high-grade aluminum.

The name “80/20” itself comes from the company’s claim: you can build structures that are 80% complete in just 20% of the time compared to traditional methods. This idea is inspired by the 80/20 principle (also known as the Pareto Principle), which suggests that a small portion of effort often delivers the majority of results. Here, the system enables rapid assembly and flexibility, letting you focus on what matters most in your project.

It’s important to note that 8020 aluminum isn’t defined by its chemical makeup, but by its function as a modular building system. However, the 8020 aluminum material used in these extrusions is typically 6105-T5 aluminum alloy. This alloy belongs to the 6000 series—known for its excellent strength, corrosion resistance, and machinability. The composition generally includes:

The manufacturing process involves extrusion: aluminum billets are heated and forced through a die to form the distinctive T-slot profile. After extrusion, the material is heat-treated (often to the T5 temper) to maximize its mechanical properties, resulting in profiles that are both strong and lightweight.

The core value of 8020 aluminum is simple: it empowers you to create custom structures with minimal tools, no welding, and endless flexibility.

Thanks to this unique combination of modularity and material strength, 8020 aluminum has become a go-to solution for engineers, manufacturers, and makers alike. Whether you’re building a machine frame, a display stand, or a home workshop upgrade, this system offers a level of adaptability and ease that traditional materials simply can’t match.

When you first encounter 8020 t slot aluminum, it may look like just another metal bar. But take a closer look, and you’ll notice the signature T-shaped channels running along each side. These are the heart of the system—and the secret behind its incredible flexibility. So, how exactly does this clever design work, and why has it become the backbone of so many modern projects?

Imagine building with blocks that can be connected, moved, and rearranged at any time. That’s the essence of 8020 aluminum extrusion. The T-slot channel acts as a universal track, allowing you to slide in specialized fasteners, brackets, and accessories anywhere along its length. This means you can mount shelves, attach panels, or join multiple profiles together—without drilling holes or making permanent modifications.

Here’s how it typically works:

Compare this to traditional steel frames, where every change means cutting, drilling, or even welding. With aluminum extrusion 8020, you can reconfigure, expand, or repair your structure in minutes—often with nothing more than a hex key.

Why choose a 8020 t slot aluminum extrusion system over welded steel or custom-cut wood? The answer lies in four major benefits that make this approach a favorite for engineers, manufacturers, and DIYers alike:

According to industry experts, this modular approach "simplifies the construction process and provides flexibility in design modifications," making it suitable for everything from industrial automation to creative DIY setups.

As you’ll see in the next section, this adaptability extends to a wide range of profile sizes and series, giving you even more control over your project’s design and performance.

Ever tried to design a custom frame and found yourself lost in a sea of profile numbers like 1010, 1515, or 8040? You’re not alone. Choosing the right 8020 aluminum extrusion dimensions is one of the most important—and confusing—steps in any project. Let’s break down what these numbers mean, how they relate to different series, and how to pick the best fit for your needs.

When you see terms like 8020 aluminum 1010 or 8020 aluminum 1515, you’re looking at a shorthand for the profile’s size and series. Each series is designed for specific applications, balancing strength, weight, and cost. Here’s how the most common series compare:

| Series Name | Profile Dimensions | Typical Applications | Relative Strength/Cost |

|---|---|---|---|

| 10 Series | 1" x 1" (1010), up to 2" x 4" (2040) | Light-duty frames, enclosures, small workstations | Lower strength, lowest cost |

| 15 Series | 1.5" x 1.5" (1515), up to 3" x 6" (3060) | Machine guards, medium-duty automation, larger workbenches | Medium strength, moderate cost |

| 25 Series / Metric | 25mm x 25mm, up to 50mm x 100mm | Metric-based machinery, European-standard projects | Varies by size, generally similar to 10/15 Series |

| 40 Series / 8040 | 40mm x 40mm, 80mm x 40mm (8040), up to 80mm x 80mm | Heavy-duty automation, industrial frames, large equipment | Highest strength, higher cost |

As you move up in series, profiles get larger and stronger—but also heavier and more expensive. For example, the 1010 profile is perfect for lightweight projects, while the 1515 or 8040 extruded aluminum profiles are better suited for industrial automation or machine bases where rigidity is key.

Still unsure which profile to choose? Here are a few practical scenarios to help you decide:

For even more insight into the versatility of the 8040 profile, check out this in-depth blog post on 8040 aluminum extrusions. It covers real-world applications, design tips, and the benefits of choosing the right profile for your project.

Imagine you’re building a custom machine frame. If you choose a profile that’s too light, you risk flex and instability. Go too heavy, and you waste material and budget. The key is to match the 8020 aluminum extrusion dimensions to your project’s demands—balancing strength, cost, and ease of assembly.

Profiles like the 8040 stand out for their strength-to-weight ratio and adaptability, making them a top choice for industrial automation, machine guards, and even architectural frameworks. Their modular nature means you can scale up or down as your needs evolve, ensuring long-term flexibility and value.

As you plan your next build, take time to compare series, dimensions, and real-world requirements. The right choice will save you time, money, and headaches—while unlocking the full potential of your 8020 extruded aluminum system. Next, let’s see how these profiles come to life in actual projects and innovative applications.

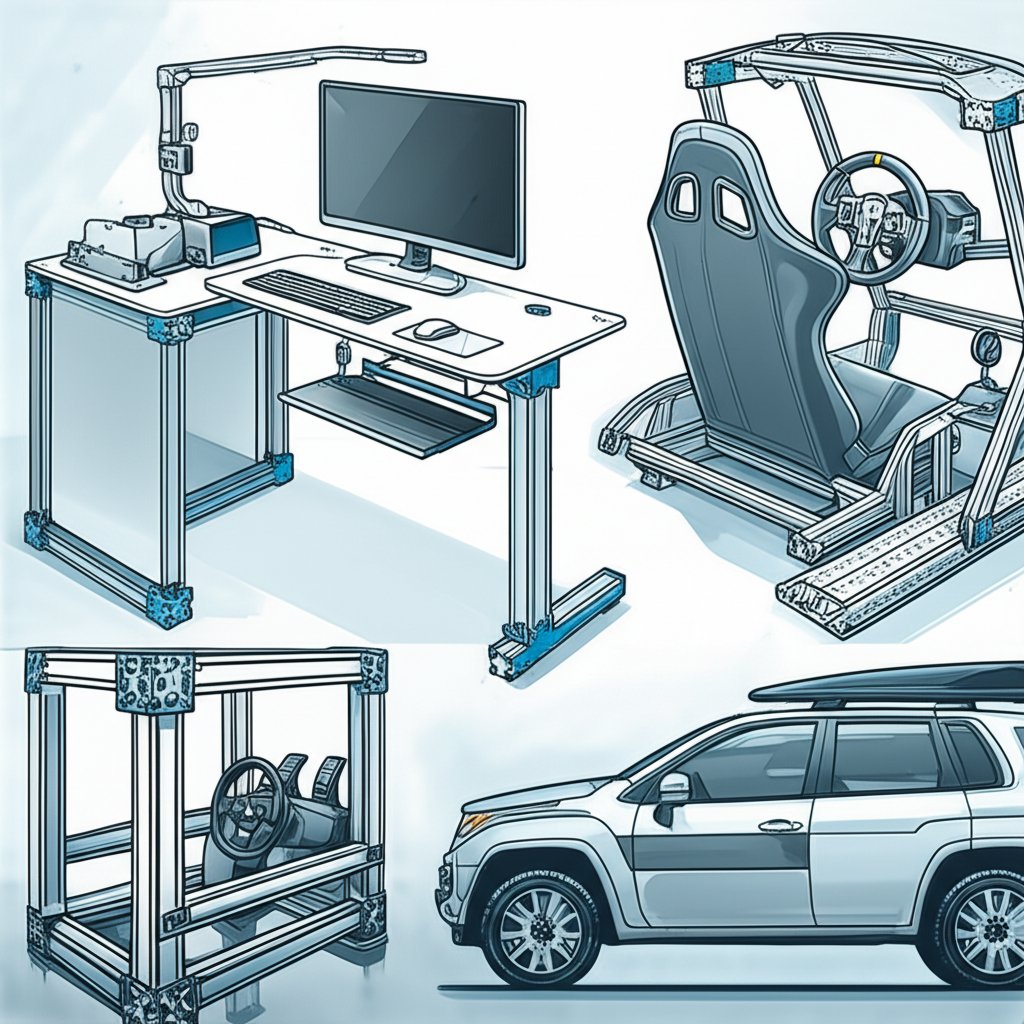

When you start exploring what you can build with modular T-slot aluminum, it’s easy to feel overwhelmed by the possibilities. Need a sturdy workbench that can evolve as your projects do? Or maybe you dream of a customized sim racing rig or a robust roof rack for your next adventure. With 8020 aluminum, these ideas—and countless others—are within easy reach. Let’s break down how this system is transforming industries, hobbies, and homes alike.

So, what are some of the most common 8020 aluminum projects? Whether you’re a professional fabricator or a weekend DIYer, you’ll find that T-slot extrusions offer a solution for almost any structural challenge. Below are real-world categories and examples to spark your imagination:

Imagine you’re planning your next project. Why settle for off-the-shelf solutions that only almost fit your needs? With 8020, you can:

Ultimately, the versatility, strength, and reusability of 8020 aluminum make it an ideal foundation for both professional and personal projects. Whether you’re tackling industrial automation, outfitting your home workshop, or building something entirely new, this system gives you the freedom to design, build, and evolve—one T-slot at a time.

Next, we’ll dive into the best practices for designing and assembling your frame, ensuring your project is both strong and easy to build.

When you’re ready to turn your ideas into a sturdy, reliable 8020 aluminum frame, a little planning goes a long way. Maybe you’re building a custom workstation, a machine enclosure, or a sim rig—whatever the project, success hinges on smart design, the right connectors, and precise assembly. Sounds complex? Let’s break it down into simple, actionable steps so you can build with confidence and efficiency.

Before you even pick up a saw, spend some time sketching your project and considering its requirements. Ask yourself: What loads will the frame support? Will it need to handle dynamic forces, like moving machinery or frequent adjustments? The answers will guide your profile and fastener choices.

One often-overlooked tip:

Always double-check your fastener compatibility with your chosen profile series.

Using the wrong size or type can reduce strength and make assembly much harder than it needs to be.

Wondering which connectors and fasteners make the most sense for your frame? Here’s a quick guide to the essentials, with practical examples:

Your choice of fastener should reflect your project’s needs. For example, internal fasteners are ideal for a clean look on furniture, while external brackets make it easier to adjust and reconfigure industrial setups.

Accurate, clean cuts are crucial for a professional finish and a square, stable frame. Here’s how to get it right:

Imagine you’re assembling a modular workbench. By measuring twice, cutting once, and methodically tightening each fastener, you create a frame that’s rock-solid and ready for years of use. Need to expand or modify it later? Just loosen the connectors, add new profiles, and keep building—no need to start from scratch.

By following these best practices for design, fastener selection, and assembly, you’ll unlock the full potential of your 8020 aluminum extrusions. Next, let’s see how this system compares to steel and wood, helping you make the smartest material choice for your next project.

When you’re planning a new frame, enclosure, or custom workstation, one of the first questions is: “Should I use 8020 aluminum, welded steel, or wood?” Each material has its own set of strengths and trade-offs, and the best choice depends on your project’s unique needs. Let’s break down the most important factors—so you can decide with confidence.

Imagine you’re building an automation frame or a heavy-duty workbench. Welded steel is the traditional go-to, but modular aluminum systems like 8020 are gaining ground fast. Why? It comes down to more than just strength. Here’s a side-by-side look at the key differences, based on industry data and real-world experience (GCG Blog):

| Feature | 8020 Aluminum | Welded Steel | Wood |

|---|---|---|---|

| Ease of Assembly | No welding; assemble with simple tools. Easily reconfigurable. | Requires welding, cutting, and specialized skills. Permanent joints. | Basic tools required. Easy for simple projects, but less precise for complex builds. |

| Adjustability / Modularity | Highly modular. Profiles and accessories can be repositioned or reused. | Low. Modifications require cutting/welding. Not designed for reconfiguration. | Low to moderate. Adjustments often mean rebuilding or patching. |

| Weight | Lightweight—about 1/3 the weight of steel. Easy to transport and move. | Heavy. Requires more support and effort to move or assemble. | Moderate. Heavier than aluminum, lighter than steel, but can be bulky. |

| Corrosion Resistance | Excellent—naturally resistant to rust and weathering. Great for indoor/outdoor use. | Needs primer or paint to prevent corrosion. Susceptible to rust if left untreated. | Poor. Prone to rot, warping, and insect damage—especially in wet or outdoor environments. |

| Initial Cost vs. Lifetime Value | Moderate initial cost; lower lifetime cost due to reusability and low maintenance. | Higher initial cost and labor; long-lasting but limited flexibility. | Lowest upfront cost, but higher lifetime costs due to maintenance and shorter lifespan. |

What does this mean in practice? If you need a frame that’s easy to assemble, modify, and move—or if you want to repurpose your materials down the line—aluminum 8020 is hard to beat. Steel is the king of rigidity and load-bearing, but you trade off adjustability and ease of assembly. Wood is budget-friendly for basic, low-stress projects, but it simply can’t match the precision, durability, or reusability of metal systems.

Let’s say you’re weighing 8020 aluminum vs. a traditional wooden frame for a workbench or a custom rack. At first glance, wood seems like the obvious choice—cheap, familiar, and easy to cut. But dig a little deeper, and the benefits of aluminum become clear:

When it comes to 2020 vs 8020 aluminum extrusion or 8020 vs 2020 aluminum, the differences are mainly in profile size, strength, and application—but both offer the core advantages that set aluminum apart from steel and wood: modularity, corrosion resistance, and ease of use.

In summary, if your project values flexibility, longevity, and a clean, modern look, 8020 aluminum is a smart investment—outperforming wood in durability and steel in adaptability. Next, let’s explore how your material choice impacts your project’s overall cost and what to expect when budgeting for your build.

Ever started planning a custom frame or workstation, only to get sticker shock when you add up the costs? You’re not alone. Budgeting for a project using 8020 aluminum means understanding more than just the price per foot. Several key factors influence the final cost—and knowing them up front can help you save money, avoid surprises, and make smarter decisions.

Let’s break down what actually goes into your project’s budget. Imagine you’re building a modular workbench or machine guard. The final price depends on several variables, not just the list price of the aluminum profiles. Here’s what you need to consider:

Want to find cheap 8020 aluminum for your build? It’s not just about finding the lowest sticker price. Consider these additional factors that affect your bottom line:

Imagine you need eight short segments for a project. Ordering them pre-cut from a supplier means paying a cut fee for each piece. Instead, buying a single long extrusion and cutting it yourself can be much more budget-friendly—especially for simple profiles and if you already own the necessary saw or jig.

Ultimately, the smartest approach is to plan your design carefully, compare sourcing options, and weigh the trade-offs between DIY and supplier services. By understanding what drives the cost of 8020 aluminum, you’ll be better equipped to budget accurately—and avoid costly surprises as your project takes shape.

Next, let’s look at how to source your aluminum profiles and why partnering with a professional manufacturer can make all the difference for larger builds.

After mapping out your design and budget, the next big question is: where to buy 8020 aluminum that meets your needs for quality, price, and customization? Whether you’re building a single workstation or outfitting an entire manufacturing line, sourcing the right 8020 aluminum profile can make or break your project’s success. Let’s explore your best options and why your choice of supplier matters more than ever.

Imagine you’re ready to kick off your build. Do you head to a local metal shop, browse online, or connect with a manufacturer directly? Each route offers unique benefits—and knowing when to use which can save you time, money, and headaches.

For businesses and large-scale projects, partnering with a professional aluminum profile manufacturer like Shengxin Aluminum in China can offer significant advantages in cost and customization. Why consider this approach? Imagine you’re outfitting a factory, constructing automation frames, or launching a product line—every dollar and every detail counts.

As the global aluminum supply chain continues to evolve, smart sourcing is about more than just price—it’s about reliability, flexibility, and long-term value. Whether you’re searching for a quick solution or planning a major build, consider your project’s size, complexity, and customization needs when choosing where to buy 8020 aluminum.

By weighing your sourcing options and partnering with the right supplier, you’ll ensure your next project is built on a foundation of quality and efficiency—ready to meet the demands of 2025 and beyond.

The name '80/20 aluminum' comes from the 80/20 company, which created and patented the modular T-slot framing system in 1979. The name also references the 80/20 principle, highlighting the system's efficiency—allowing users to complete most of a build with minimal effort compared to traditional methods.

40x40 and 80x20 refer to metric profile dimensions, with 40x40mm and 80x20mm being common T-slot extrusion sizes. 8020 aluminum generally offers a higher strength-to-weight ratio, making it suitable for robust applications, while 4040 balances strength and weight for medium-load projects. Choosing between them depends on your project's load and size requirements.

8020 aluminum profiles are highly resistant to corrosion and do not rust like steel. Their natural oxide layer and typical anodized finish make them suitable for both indoor and outdoor use, minimizing maintenance and ensuring long-term durability.

8020 aluminum systems are modular, lightweight, and easy to assemble with basic tools—no welding required. They allow for rapid adjustments, reusability, and custom configurations, unlike welded steel, which is heavier, less flexible, and requires specialized skills for modifications.

For large-scale or custom needs, sourcing directly from manufacturers like Shengxin Aluminum in China offers cost savings, customization options, and quality assurance. They provide bulk ordering, tailored profiles, and advanced finishes, making them ideal for businesses and industrial applications.

dịch vụ trực tuyến

dịch vụ trực tuyến 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360