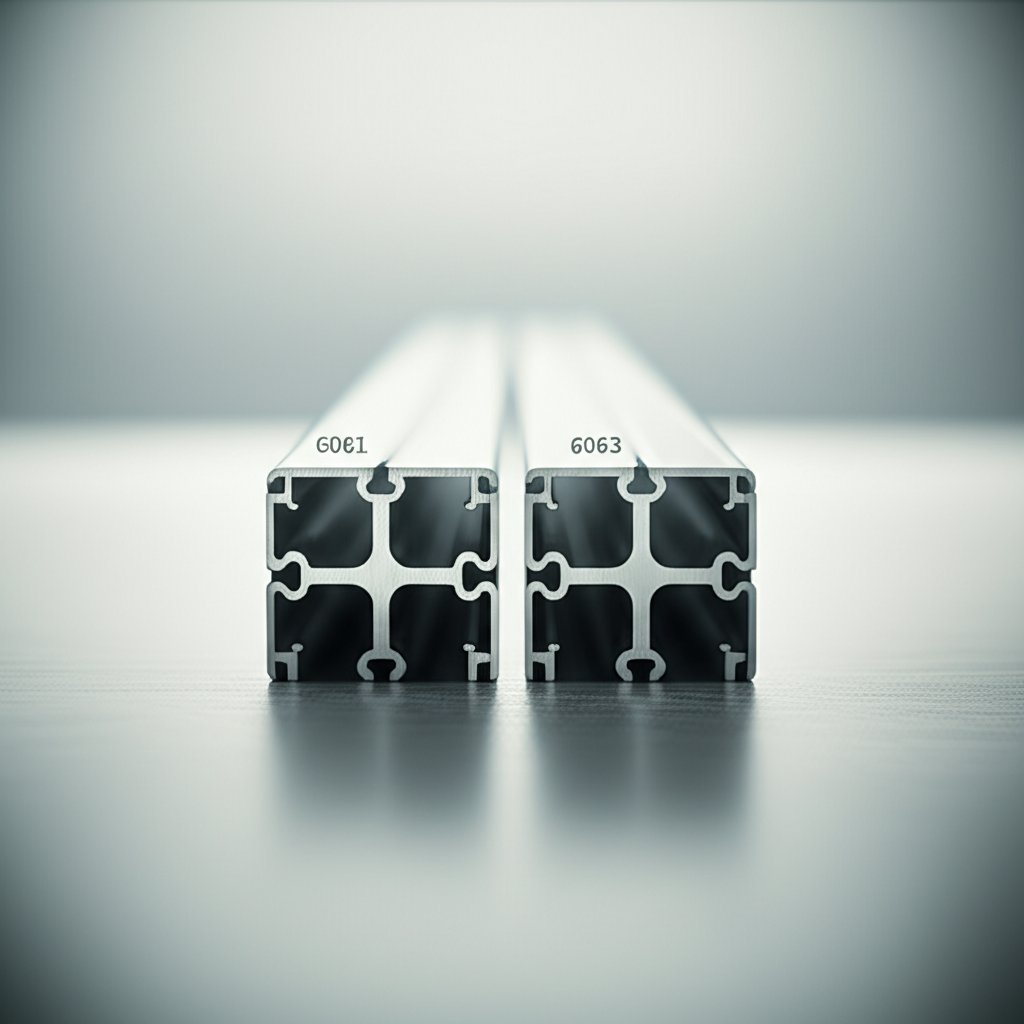

Ever found yourself weighing the pros and cons of different aluminum alloys for your next project? If you’re searching for the best balance of strength, workability, and finish, there’s a good chance you’ve come across aluminum 6061 vs 6063. These two alloys are among the most widely used choices for extruded aluminum products, but understanding their differences isn’t always straightforward.

Imagine you’re designing a sleek architectural frame or a rugged machine part. The alloy you select will shape not just the look and feel of your final product, but also its performance, ease of fabrication, and overall cost. That’s why the debate around 6061 vs 6063 aluminum is so important for engineers, architects, and anyone working with aluminum extrusions.

But here’s where things can get confusing: both alloys belong to the same 6xxx series, share similar alloying elements, and even overlap in some applications. So, how do you choose the right one?

This article is designed to clear up the confusion. We’ll break down the key differences between 6061 and 6063—covering everything from their chemical compositions and mechanical strengths to their workability, corrosion resistance, and typical price points. By the end, you’ll have a clear, practical understanding of which alloy best fits your specific needs, ensuring your next aluminum project is a success (Kloeckner Metals).

Ready to make an informed choice? Let’s dive into the essential differences between these two powerhouse alloys.

When you’re faced with the decision between 6063 vs 6061 aluminum, it’s easy to feel overwhelmed by the similarities. Both are part of the 6000 series, share magnesium and silicon as primary alloying elements, and are popular for extrusions. But if you look closer, the differences become clear—and choosing the right alloy can make a world of difference for your project’s performance, appearance, and cost.

Let’s break down the core contrasts in a way that’s quick to scan and easy to apply. Imagine you’re selecting material for a high-strength machine part or a modern window frame. Which alloy should you choose? Here’s how aluminum alloy 6061 vs 6063 stack up in the key categories:

| Property | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Strength | Higher tensile and yield strength; ideal for structural and load-bearing applications | Lower strength; suitable for non-critical or decorative uses |

| Formability / Extrudability | Good, but less suited to highly complex or thin-walled shapes | Excellent; easily extruded into intricate profiles and thin sections |

| Surface Finish | Acceptable finish; not as smooth as 6063, less ideal for visible surfaces | Superior finish; highly suitable for anodizing and decorative applications |

| Corrosion Resistance | Very good, but slightly less than 6063 due to higher copper content | Excellent; performs well in architectural and outdoor settings |

| Machinability | Excellent; handles machining well, making it a favorite for parts requiring precision | Good; fair machinability, but not as robust as 6061 |

| Typical Applications | Structural frames, automotive parts, aerospace components, bike frames, fixtures | Window frames, door frames, architectural trim, railings, display units |

Ultimately, the choice between these two comes down to balancing strength, finish, and fabrication needs. Up next, we’ll dig deeper into the chemistry behind these alloys to show how their compositions influence performance—so you can make an even more informed decision.

Ever wondered why two alloys from the same family—like 6061 and 6063—perform so differently? The answer lies in their chemical makeup. Let’s break down what’s inside these alloys and see how even small changes can lead to big differences in strength, formability, and finish.

Both 6061 and 6063 are part of the 6000 series, which means they’re primarily alloyed with magnesium and silicon. But here’s where things get interesting: the actual amounts of these elements vary between the two, and that’s what shapes their unique characteristics.

Here’s a quick reference table to help you visualize the typical composition ranges for each alloy (Gabrian):

| Element | 6061 (%) | 6063 (%) |

|---|---|---|

| Magnesium (Mg) | 0.8 – 1.2 | 0.45 – 0.9 |

| Silicon (Si) | 0.4 – 0.8 | 0.2 – 0.6 |

| Copper (Cu) | 0.15 – 0.4 | ≤ 0.1 |

| Chromium (Cr) | 0.04 – 0.35 | ≤ 0.1 |

| Iron (Fe) | ≤ 0.7 | ≤ 0.35 |

| Aluminum (Al) | Balance | Balance |

It might sound technical, but understanding al 6061 vs 6063 composition helps you pick the right alloy for your project’s demands. Need strength and machinability? 6061 is your answer. Looking for beautiful, complex shapes and a flawless finish? 6063 is built for the job.

Up next, we’ll see how these compositional differences translate into real-world mechanical performance—so you can match the right alloy to your application’s requirements with confidence.

When it comes to picking the right aluminum alloy for your project, mechanical strength is often the deal-breaker. But what does “strength” really mean in the context of 6061 vs 6063 strength? Let’s break it down using real numbers, practical scenarios, and a side-by-side comparison that makes your decision easier.

First, a quick primer: “Temper” refers to the heat treatment process that an aluminum alloy undergoes to achieve certain mechanical properties. The most common tempers you’ll see for these alloys are:

Why does this matter? Because the temper dramatically influences properties like tensile strength, yield strength, and hardness. For structural or high-stress applications, the right temper can be just as important as the alloy itself.

Let’s get specific. Imagine you’re designing a load-bearing frame or a decorative trim. Here’s how the numbers stack up for the most common tempers:

| Property | 6061-T6 | 6063-T5 | 6063-T6 (approx.) |

|---|---|---|---|

| Tensile Strength (Ultimate, MPa) | 310 | 180 | 205 |

| Yield Strength (MPa) | 270 | 140 | 170 |

| Hardness (Brinell) | 95 | 73 | 75–80 |

| Elongation at Break (%) | 10 | 11 | 8–10 |

| Fatigue Strength (MPa) | 96 | 70 | 75–80 |

You might wonder, “What about 6063 t52 vs 6061 t6?” T52 is a temper of 6063 designed to enhance ductility, making it easier to bend without cracking. While it still doesn’t match the mechanical strength of 6061-T6, it’s the go-to for projects involving intricate bends or shapes—like curved railings or custom architectural elements.

Key takeaway: If your project’s success hinges on strength and durability, 6061-T6 is the clear winner. If you need smooth finishes and intricate profiles, 6063’s tempers offer the flexibility and surface quality you want.

Now that you’ve seen how mechanical properties set these alloys apart, let’s explore how their workability—machinability and bending—can influence your final choice.

When it comes to transforming aluminum extrusions into finished parts, workability is just as important as strength or surface finish. If you’ve ever wondered, “Which is easier to machine or bend: 6061 or 6063?”—you’re not alone. Let’s break down the practical differences in 6061 vs 6063 machinability and 6061 vs 6063 bending so you can confidently match alloy to application.

Imagine you need to mill, drill, or cut your aluminum profile into a precise component. The way an alloy responds to machining—how it forms chips, wears tools, and finishes—is crucial for cost, speed, and part quality.

| Machining Factor | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Chip Formation | Forms clean, consistent chips; less likely to gum up tools | Tends to produce softer, stringier chips; can clog tools if not managed |

| Tool Wear | Low to moderate; suitable for high-speed machining | Moderate; slightly higher due to softer material and tendency to adhere |

| Surface Finish After Machining | Good to excellent; can achieve tight tolerances and smooth surfaces | Fair to good; finish is acceptable, but not as crisp as 6061 |

| Machinability Rating | Good (preferred for precision parts) | Fair (adequate for less demanding applications) |

In short, if your project demands intricate machining or tight tolerances, 6061 is the better choice. Its harder composition makes it less prone to tool clogging and delivers a more predictable finish (Triad Products).

What if your design calls for sharp bends, curves, or complex profiles? Here’s where the differences between 6061 vs 6063 bending really come to light.

| Bending Factor | 6061 | 6063 |

|---|---|---|

| Minimum Bend Radius | Larger (needs gentle bends to avoid cracking) | Smaller (handles tighter bends with less risk) |

| Suitability for Complex Forms | Moderate; limited by risk of cracking in hard tempers | Excellent; ideal for intricate, decorative, or thin-walled profiles |

If your project involves custom tube bending or elaborate extrusions, 6063’s flexibility will save time and reduce scrap. On the other hand, for applications where strength after bending is paramount, 6061 remains the top pick (Gabrian).

Sounds complex? That’s because achieving the right balance of machinability and bendability isn’t just about picking the right alloy—it’s about working with a manufacturer who knows how to maximize each material’s strengths. Precision machining, tight-tolerance bending, and complex forming require advanced equipment and deep technical know-how.

This is where experienced partners like Shengxin Aluminum add value. With extensive deep-processing capabilities and a full suite of extrusion, machining, and finishing lines, Shengxin can help you realize even the most challenging aluminum designs—whether you need perfectly machined parts from 6061 or complex, smoothly bent profiles in 6063.

Key takeaway: For high-precision machining, 6061 is your go-to. For complex shapes or tight bends, 6063 shines. Either way, choosing a skilled manufacturer ensures your aluminum profiles perform as designed.

Next, let’s see how these alloys stand up to the elements, as we compare their corrosion resistance and anodizing capabilities.

Ever wondered why some aluminum structures keep their shine year after year, while others dull or pit over time? When choosing between 6061 vs 6063 aluminum for outdoor or visible applications, understanding corrosion resistance and anodizing potential is crucial. Let’s break down how these two alloys perform against the elements and what happens when you want that perfect, durable finish.

Imagine you’re designing window frames, railings, or outdoor signage. Exposure to rain, humidity, and even salty air can wear down most metals. The good news? Both 6061 and 6063 offer impressive natural corrosion resistance thanks to their aluminum oxide layer. But there are subtle differences worth noting:

In short, both alloys will stand up well to everyday weather, but 6063 takes the lead for projects where long-term atmospheric exposure is a concern.

When aesthetics and extra protection matter, anodizing is the go-to finishing process. But how do these alloys compare when it comes to anodizing?

Sounds complex? Here’s the process in simple terms:

This thicker oxide layer not only enhances corrosion resistance but also allows for vibrant, long-lasting colors that won’t flake or peel like paint. That’s why anodized 6063 is so popular for visible building elements and consumer products.

Key takeaway: For maximum corrosion resistance and a flawless anodized finish, 6063 is usually the better choice—especially for architectural or decorative projects. 6061 still offers solid protection and can be anodized, but is best reserved for structural roles where appearance is less critical.

Next, let’s explore how these alloys perform when it comes to welding—another key factor if your project involves assembly or joining aluminum components.

When your project calls for joining aluminum components, weldability becomes a top concern. You might be asking, “Is there a big difference in 6061 vs 6063 welding?” While both alloys are commonly welded using MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) processes, each has its own quirks and considerations. Let’s break down what you need to know before you strike an arc.

Both 6061 and 6063 are weldable with standard aluminum welding techniques—MIG and TIG being the most popular. Here’s how they compare:

The filler metal you select is crucial for weld strength and integrity. For both 6061 and 6063, the most common filler alloys are:

For most applications, ER4043 is the go-to choice, especially when welding 6061 or 6063 extrusions for architectural or general fabrication projects (Gabrian).

| Aspect | 6061 Aluminum | 6063 Aluminum |

|---|---|---|

| Weldability | Good, but more prone to hot cracking; careful prep and filler selection required | Very good; less sensitive to cracking, easier to weld for decorative or thin profiles |

| Heat-Affected Zone (HAZ) Strength | Significant loss of strength in the HAZ after welding, especially in T6 temper | Also loses strength in the HAZ, but the impact is less critical for non-structural uses |

| Post-Weld Appearance | Can be slightly rough or discolored; may require finishing for visible joints | Smoother, more uniform welds; better for applications where aesthetics matter |

| Recommended Filler | ER4043 or ER5356 (with caution) | ER4043 |

When welding either alloy, the area next to the weld—the HAZ—experiences a drop in mechanical strength. This is particularly important for 6061-T6, which can lose a significant portion of its original strength due to the dissolution of strengthening precipitates during welding. While post-weld heat treatment can restore some properties, it’s not always practical for large assemblies or finished structures.

Summary: If your project involves visible, decorative welds or non-critical joints, 6063 is your friend. For load-bearing or structural welds, 6061 is suitable but demands extra care to compensate for HAZ strength loss. Choosing the right filler and understanding the effects of welding on mechanical properties are essential for a successful outcome.

Next, we’ll look at how to match the right alloy to your application—whether you’re building a frame, a railing, or a custom extrusion—so you can make the best choice for your project’s needs.

Faced with the decision between 6061 and 6063 aluminum for your next project? It’s not always obvious which alloy will deliver the best results. Should you prioritize strength, surface finish, or the ability to create complex shapes? Let’s break down how to choose the right alloy for your application, using real-world scenarios and practical examples—so you can match material to need with confidence.

Imagine you’re designing a bike frame, a structural support, or an architectural railing. The choice between 6061 vs 6063 aluminum tubing can make a significant impact on performance, durability, and appearance. Here’s how their strengths play out in typical applications:

| Application | Best Alloy | Why? |

|---|---|---|

| Structural frames (e.g., machine bases, bike frames) | 6061 | Superior strength and stiffness; handles higher loads |

| Architectural tubing (window, door frames, railings) | 6063 | Excellent surface finish and extrudability; ideal for visible, decorative elements |

| Custom extrusions with intricate shapes | 6063 | Best for complex profiles and thin-walled sections |

| Machined parts requiring tight tolerances | 6061 | Better machinability and dimensional stability |

| Outdoor or marine applications | 6063 | Superior corrosion resistance and anodizing finish |

| Heavy-duty brackets, fixtures, or automotive parts | 6061 | Higher load-bearing capacity and fatigue strength |

Still unsure which alloy is right for your needs? Here are practical questions to guide your selection:

You might also encounter 6060 aluminum, which sits between 6061 and 6063 in terms of strength and extrudability. While 6060 offers good corrosion resistance and is easy to extrude, it’s less common in North American markets compared to 6061 and 6063. For most applications, you’ll find that 6061 and 6063 cover the majority of needs, but if you require a balance between strength and intricate shapes, 6060 could be worth considering as well (Kloeckner Metals).

Sounds complex? That’s where working with an experienced aluminum profile manufacturer like Shengxin Aluminum makes all the difference. Shengxin offers a broad range of manufacturing and finishing services, from precision extrusion and deep processing to anodizing and powder coating. Whether you need high-strength 6061 tubing for industrial machinery or flawless 6063 extrusions for architectural features, Shengxin’s advanced production lines and technical expertise ensure your project requirements are met—down to the last detail.

Key takeaway: Let your project’s priorities—strength, finish, formability, or corrosion resistance—guide your alloy choice. And when in doubt, consult with a manufacturer who can help you navigate the nuances of 6061 vs 6063 aluminum tubing and beyond.

Next, let’s look at how pricing factors into your decision, so you can balance performance and budget for your aluminum project.

Ever wondered why two seemingly similar aluminum alloys can come with very different price tags? If you’re deciding between 6061 vs 6063 cost for your next project, it’s important to look beyond the base material price and consider the full range of factors that influence the final bill. Let’s break down what really drives the 6061 vs 6063 price—so you can budget smart and avoid surprises.

At first glance, you might assume all extrudable aluminum alloys are priced similarly. In reality, several variables play a role, and understanding them can help you make the most cost-effective choice for your application.

For most standard extrusions, 6063 is often less expensive than 6061. Its superior extrudability means lower production costs for profiles like window frames, rails, and decorative trim. However, if your application requires the higher strength and machinability of 6061, expect to pay a premium for those enhanced properties (BOYI Prototyping).

| Cost Factor | 6061 | 6063 |

|---|---|---|

| Raw Material Cost | Higher (due to alloying elements) | Lower |

| Extrusion Complexity | More challenging, higher cost for complex shapes | Easy to extrude, lower cost for most profiles |

| Heat Treatment | Additional cost for high-strength tempers (T6) | Less intensive, often lower cost |

| Finishing | May require more prep for decorative use | Smoother as-extruded, lower finishing cost |

| Application Suitability | Best for high-strength, precision parts | Best for decorative, architectural profiles |

Key takeaway: The price difference between 6061 and 6063 aluminum is shaped by alloy composition, processing requirements, finishing needs, and market factors. While 6063 is usually more budget-friendly for standard shapes, your project’s technical demands may justify the extra investment in 6061. Weigh your priorities carefully to strike the right balance between performance and cost.

With a clear understanding of cost variables, you’re now equipped to make a financially sound decision. In the final section, we’ll recap the key takeaways and help you chart the best path forward for your aluminum project.

Still wondering which aluminum alloy is the best fit for your needs? Choosing between 6061 vs 6063 might seem like a technical hurdle, but it really comes down to understanding your project’s priorities. Let’s recap the essential points so you can move forward with confidence—and get the results you want.

Sounds complex? You don’t have to navigate the 6061 vs 6063 decision alone. Each project has unique requirements, and the right alloy choice can maximize performance, appearance, and cost-effectiveness. That’s why consulting with experienced suppliers or material experts is invaluable—they can help you weigh trade-offs and optimize your design from the start.

For those seeking a reliable partner, Shengxin Aluminum offers deep technical expertise and a broad portfolio of high-quality extrusions in both 6061 and 6063. Whether you need robust structural profiles or flawless architectural finishes, Shengxin’s advanced production lines and finishing capabilities ensure your project goals are met—efficiently and precisely.

Final thought: The best alloy for your project is the one that aligns with your priorities—be it strength, finish, formability, or budget. Don’t hesitate to reach out to knowledgeable suppliers like Shengxin Aluminum for tailored advice and premium extrusions that bring your vision to life.

Ready to take the next step? Explore Shengxin’s full range of aluminum solutions and let their team help you turn your ideas into reality—no guesswork required.

6061 aluminum is stronger and better for structural, load-bearing applications, while 6063 offers a smoother surface finish and is preferred for intricate extrusions and decorative architectural uses. The choice depends on whether strength or appearance is your priority.

Both 6061 and 6063 are weldable using MIG or TIG methods, but 6063 is generally easier to weld and less prone to cracking. 6061 requires careful filler selection and attention to heat-affected zones, especially in T6 temper, to maintain joint integrity.

6063 aluminum is better suited for anodizing, delivering a more uniform and attractive finish. It's widely used for visible architectural elements. 6061 can be anodized as well, but the finish may appear duller and less consistent.

6063 aluminum is most commonly used for architectural fabrication, window and door frames, railings, and decorative trim due to its excellent extrudability and surface finish. Its corrosion resistance also makes it ideal for outdoor structures.

6063 is typically less expensive for standard extrusions because it is easier to process and finish. 6061 costs more due to its higher strength and more complex composition, but it may be worth the investment for demanding structural applications.

dịch vụ trực tuyến

dịch vụ trực tuyến 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360